Looking for FLUID LINE products and services?

Flash Steam Recovery System: Maximizing Energy Efficiency

The Flash Steam Recovery System is designed to capture and reuse flash steam generated when high-temperature water or other hot liquids are depressurized. This system is commonly used in industrial processes such as power plants, chemical plants, and food processing facilities to improve energy efficiency and reduce operational costs.

What is Flash Steam?

Flash steam is formed when high-pressure condensate or hot water is released to a lower pressure environment. The sudden drop in pressure causes a portion of the liquid to instantly vaporize into steam, known as flash steam.

Importance of Flash Steam Recovery:

- Energy Savings:

Flash steam contains significant thermal energy that can be reused, reducing the need for additional steam generation and lowering energy consumption. - Cost Reduction:

Recovering and reusing flash steam reduces fuel costs and improves overall process efficiency. - Environmental Benefits:

By reusing energy that would otherwise be wasted, the system helps reduce greenhouse gas emissions and promotes sustainability. - Improved System Efficiency:

Utilizing flash steam minimizes energy losses and enhances the performance of steam systems.

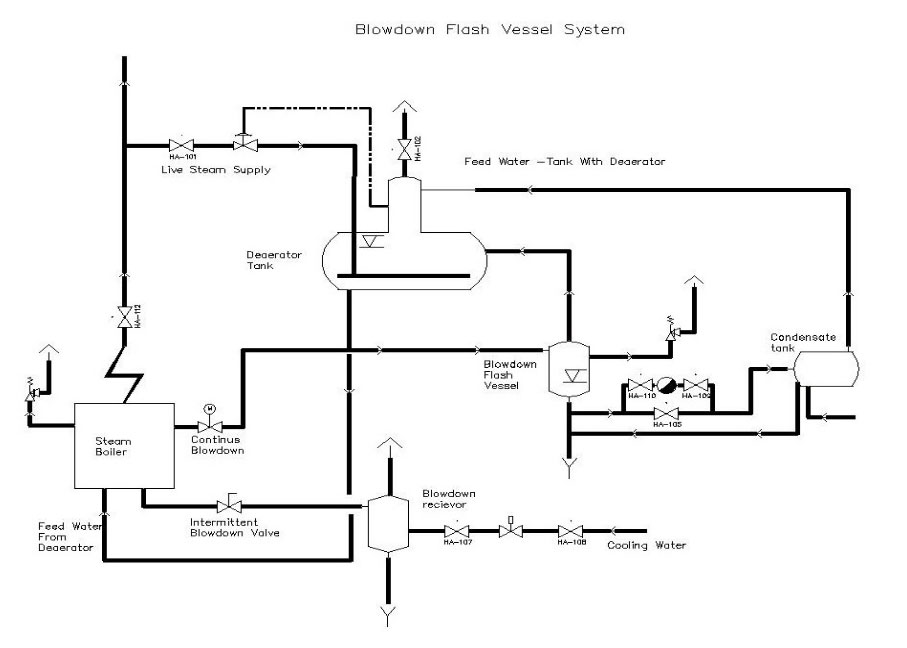

How the Flash Steam Recovery System Works:

- Condensate Release:

High-pressure condensate or hot water is released from a steam trap or other equipment. - Pressure Reduction:

The condensate enters a flash vessel or recovery tank, where the pressure is reduced, causing a portion of the liquid to flash into steam. - Steam Separation:

The flash steam is separated from the remaining liquid in the flash vessel. - Steam Reuse:

The recovered flash steam is directed to low-pressure steam systems or processes, such as heating or preheating applications. - Condensate Return:

The remaining condensate is returned to the boiler or other systems for reuse.

Key Components of the System:

- Flash Vessel:

A tank where the pressure is reduced, allowing flash steam to form and separate from the condensate. - Steam Trap:

Releases high-pressure condensate into the flash vessel. - Steam Distribution System:

Transports the recovered flash steam to low-pressure applications. - Condensate Return System:

Collects and returns the remaining condensate to the boiler or other systems.

Benefits of Flash Steam Recovery:

- Energy Efficiency:

Recovers valuable thermal energy that would otherwise be wasted. - Cost Savings:

Reduces fuel consumption and operational costs by reusing flash steam. - Sustainability:

Lowers carbon footprint by minimizing energy waste. - Enhanced Process Performance:

Improves the efficiency of steam systems and reduces the load on boilers.

Applications:

- Power Plants:

Recovers flash steam from turbine condensate for reuse in low-pressure systems. - Chemical Plants:

Utilizes flash steam for heating or process applications. - Food Processing:

Recovers energy from condensate in cooking, sterilization, or drying processes. - Industrial Heating:

Reuses flash steam for space heating or preheating applications.

Conclusion

The Flash Steam Recovery System is a highly effective solution for capturing and reusing flash steam, maximizing energy efficiency, and reducing operational costs in industrial processes. By recovering thermal energy that would otherwise be wasted, this system not only improves the performance of steam systems but also contributes to environmental sustainability. Trust Fluid Line to provide advanced flash steam recovery solutions tailored to your specific industrial needs.

Benefits of Fash steam recovery system

| Weare Resistance | Robust Design | Generate high quality steam. | precise separate of condensate ana flash steam |

| Document | Reference Number | Download |

| Flash Vessels Type VD | TI-01-009 |