Looking for FLUID LINE products and services?

Feed Water De-aerating System: Importance and Functions

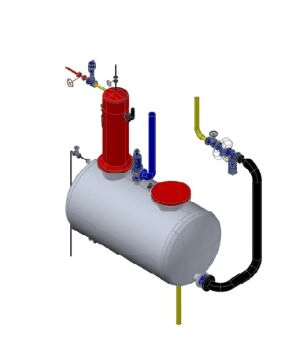

The Feed Water De-aerating System, or Deaerator, is a critical component in the steam generation process across various industries, such as power plants, manufacturing facilities, and heating systems. Its primary function is to remove unwanted gases, particularly oxygen (O₂) and carbon dioxide (CO₂), from the boiler feed water. These gases are the main causes of corrosion in steam systems, and their removal is essential for maintaining the efficiency, safety, and longevity of the boiler and associated equipment.

Importance of the Feed Water De-aerating System:

- Prevents Corrosion:

Oxygen and carbon dioxide in feed water can cause severe corrosion in boilers, pipelines, and other components. Removing these gases significantly reduces the risk of damage. - Improves Boiler Efficiency:

By eliminating gases that can form scale and deposits, the system ensures better heat transfer and operational efficiency. - Extends Equipment Life:

Reducing corrosion and scaling helps prolong the lifespan of boilers, heat exchangers, and other system components. - Ensures Safe Operation:

Prevents potential failures caused by corrosion, ensuring safe and reliable operation of the steam system. - Reduces Maintenance Costs:

Minimizes the need for frequent repairs and maintenance, lowering operational expenses.

Key Functions of the De-aerating System:

- Removal of Dissolved Oxygen (O₂):

Oxygen is highly corrosive and can cause pitting and rust in boiler tubes and pipelines. The deaerator removes oxygen to levels that are safe for the system. - Removal of Carbon Dioxide (CO₂):

Carbon dioxide can form carbonic acid in water, leading to acidic corrosion. The deaerator eliminates CO₂ to prevent this issue. - Heating the Feed Water:

The deaerator heats the feed water to near boiling temperature, which helps release dissolved gases and prepares the water for efficient steam generation. - Storage of Treated Water:

The deaerator also acts as a storage tank for treated feed water, ensuring a steady supply to the boiler.

How the De-aerating System Works:

- Preheating Stage:

Feed water is heated using steam or other heat sources to raise its temperature close to saturation. - De-aeration Stage:

The heated water is sprayed or distributed into a de-aeration chamber, where steam is used to strip away dissolved gases (O₂ and CO₂). - Ventilation:

The removed gases are vented out of the system, ensuring they do not re-enter the feed water. - Storage and Supply:

The deaerated water is stored in a tank and then supplied to the boiler for steam generation.

Benefits of the Feed Water De-aerating System:

- Corrosion Prevention:

Protects boilers and pipelines from oxygen and carbon dioxide-induced corrosion. - Improved Heat Transfer:

Ensures clean water free from gases and impurities, enhancing heat transfer efficiency. - Energy Savings:

Pre-heating the feed water reduces the energy required to convert it into steam. - Reduced Maintenance:

Minimizes scaling and corrosion, lowering maintenance costs and downtime. - Extended Equipment Life:

Protects critical components, extending the lifespan of the boiler and associated equipment.

Applications:

- Power Plants:

Ensures efficient and safe steam generation for turbines and other equipment. - Industrial Boilers:

Protects boilers in manufacturing and processing plants from corrosion. - Heating Systems:

Maintains the efficiency and longevity of heating systems in commercial and residential buildings.

Conclusion

The Feed Water De-aerating System is an indispensable part of any steam generation process. By effectively removing oxygen and carbon dioxide from boiler feed water, it prevents corrosion, improves efficiency, and ensures the safe and reliable operation of steam systems. Whether in power plants, industrial facilities, or heating systems, the deaerator plays a vital role in maintaining optimal performance and extending the life of critical equipment. Trust Fluid Line to provide high-quality de-aerating solutions tailored to your specific needs.

Benefits of DE aerating plant

| Prevent corrosion of boiler and steam equipment. | Reliable | Long service life |

| Document | Reference Number | Download |

| Feedwater DE aerating Plants D32 | TI-01-006 |