Looking for FLUID LINE products and services?

Condensate Return System: Managing Condensate for Energy Savings and Efficiency

The Condensate Return System is a system designed to collect and reuse condensate—the liquid formed when steam condenses after transferring its heat—in industrial processes or boilers. This system plays a crucial role in saving energy, reducing production costs, and improving the efficiency of steam systems across various industries.

Importance of the Condensate Return System

- Energy Savings:

Condensate returned to the system is typically at a high temperature (around 80-90°C), reducing the energy required to heat water before it enters the boiler. - Water Conservation:

Reusing condensate minimizes the need for fresh water or raw water, which would otherwise require treatment before use. - Cost Reduction:

Reusing condensate lowers steam production costs and reduces the need for water treatment chemicals. - Improved System Efficiency:

Clean, high-temperature condensate enhances boiler efficiency and performance.

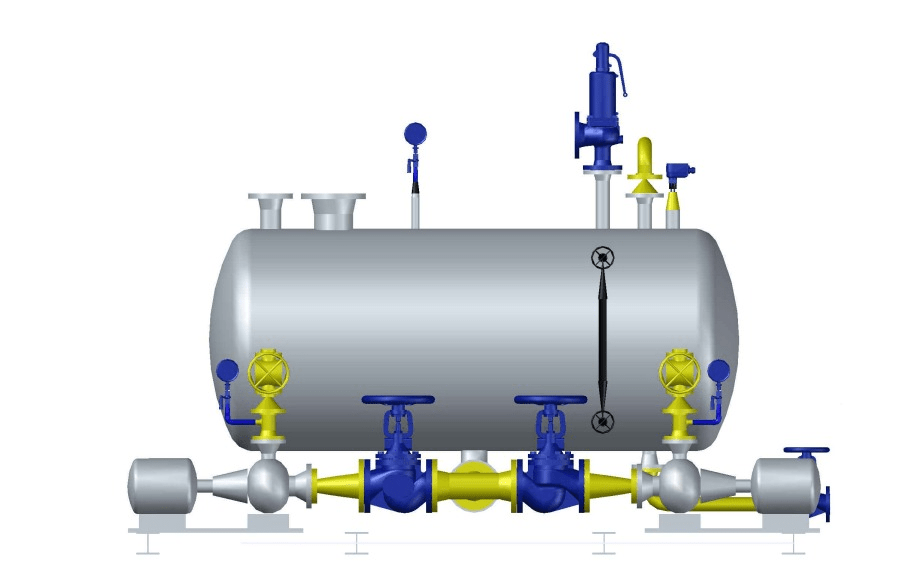

Key Components of the Condensate Return System

- Steam Trap:

A device that separates condensate from steam and discharges it from the system without allowing steam to escape. - Condensate Return Line:

Piping that transports condensate from various points of use back to the boiler or condensate tank. - Condensate Tank:

A tank that collects condensate from the system before it is returned to the boiler. - Condensate Pump:

A pump used to transport condensate from the tank back to the boiler or other points of use. - Flash Steam Recovery System:

A system that captures and reuses flash steam (steam generated when high-temperature condensate is depressurized). - Filtration System:

A filtering system that removes impurities from the condensate before it is returned to the boiler.

How the System Works

- Condensate Formation:

Steam condenses into liquid (condensate) after transferring heat in industrial processes. - Condensate Separation:

The steam trap separates condensate from steam and discharges it from the system. - Condensate Collection:

Condensate is transported through the condensate return line to the condensate tank. - Condensate Return:

The condensate pump sends the collected condensate back to the boiler or other points of use. - Flash Steam Recovery:

If the condensate is at a high temperature, depressurizing it generates flash steam, which can be captured and reused.

Benefits of the Condensate Return System

- Reduced Water and Energy Usage:

Saves fresh water and energy required for steam production. - Lower Production Costs:

Reduces expenses related to water treatment and energy consumption. - Enhanced System Efficiency:

Improves boiler performance and overall system efficiency. - Reduced Greenhouse Gas Emissions:

Energy savings contribute to lower carbon dioxide emissions.

Maintenance

- Regularly inspect and clean steam traps to prevent clogging or steam leakage.

- Check condensate return lines and condensate tanks for leaks or damage.

- Ensure condensate pumps and filtration systems are functioning efficiently.

Conclusion

The Condensate Return System is a vital component in managing energy and resources efficiently. It helps reduce production costs, improve system performance, and promote sustainability in industrial processes. By reusing condensate, industries can achieve significant energy savings, lower operational expenses, and contribute to environmental conservation.

Benefits of Condensate return system.

| Document | Reference Number | Download |

| Condensate Recovery and return system. | TI-01-008 | |

| Condensate booster pump. | TI-01-003 |

| Reduce installation costs. | Improve system performance. | Maximize system uptime. |