Looking for FLUID LINE products and services?

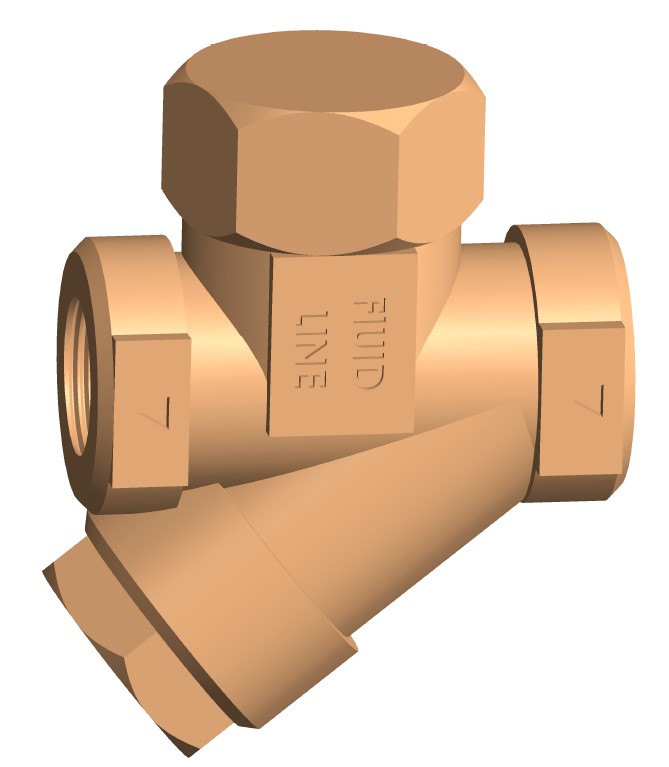

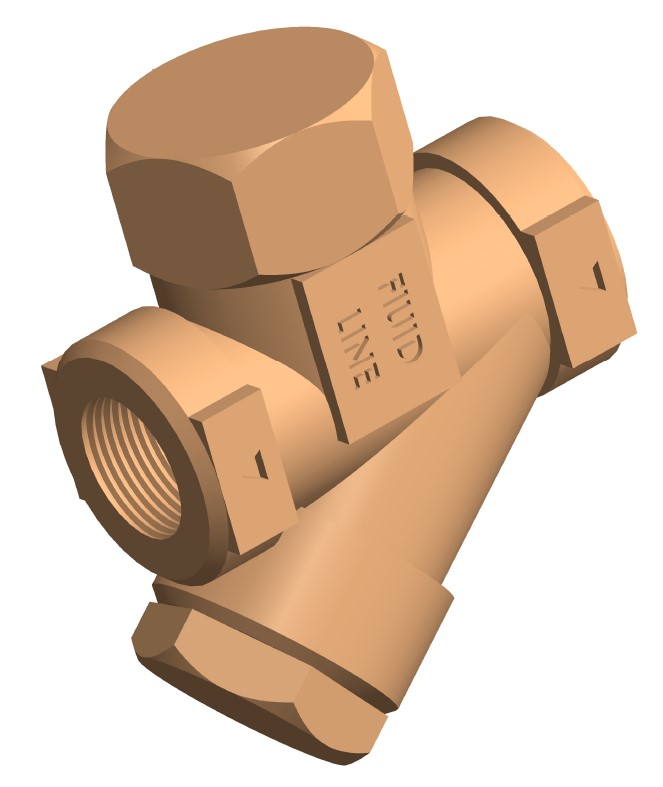

Thermodynamic Steam Trap: Importance and Function

The Thermodynamic Steam Trap is a vital component in steam systems, designed to remove condensate (water formed from condensed steam) and non-condensable gases such as air from the system. It ensures efficient steam usage by discharging condensate while preventing steam loss. This type of steam trap operates based on thermodynamic principles, which involve changes in pressure and temperature.

Key Functions of Thermodynamic Steam Traps:

- Condensate Removal:

- Effectively removes condensate from the steam system to prevent waterlogging and ensure efficient heat transfer.

- Air and Gas Venting:

- Eliminates non-condensable gases like air from the system, improving steam quality.

- Steam Retention:

- Prevents steam from escaping, ensuring that only condensate is discharged.

- Energy Efficiency:

- Maintains system efficiency by minimizing steam loss.

How It Works:

- Condensate Entry:

- Condensate enters the steam trap and flows under the disc.

- Pressure and Temperature Changes:

- When steam enters the trap, it creates a high-pressure zone above the disc, causing it to close and block steam from escaping.

- Condensate Discharge:

- As the pressure above the disc decreases, the disc opens, allowing condensate to be discharged.

- Cycle Repeats:

- The process repeats automatically, ensuring continuous condensate removal.

Benefits of Thermodynamic Steam Traps:

- Compact and Lightweight:

- Simple design with fewer moving parts, making it easy to install and maintain.

- Durability:

- Resistant to water hammer, high temperatures, and pressure fluctuations.

- Energy Efficiency:

- Minimizes steam loss, reducing energy consumption.

- Cost-Effective:

- Low maintenance and long service life make it a cost-effective solution.

Applications:

- Steam Distribution Systems: Ensures efficient condensate removal in pipelines.

- Industrial Processes: Used in industries such as food processing, chemicals, and pharmaceuticals.

- Heating Systems: Maintains efficient operation of heating systems.

- Power Plants: Protects turbines and other equipment from condensate-related damage.

Why Choose Fluid Line for Thermodynamic Steam Traps?

- Expertise: Extensive experience in designing and supplying steam traps for various applications.

- High-Quality Products: Steam traps are built to withstand harsh operating conditions.

- Custom Solutions: Tailored to meet the specific needs of your steam system.

- Comprehensive Support: From selection and installation to maintenance and troubleshooting.

By incorporating Thermodynamic Steam Traps into your steam system, you can ensure efficient condensate removal, minimize steam loss, and protect your equipment. If you need further details or assistance in selecting the right steam trap for your application, feel free to contact us!

Contact Us:

- Email: info@fluidline.net

- Phone: 085-6795642

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Steam System Efficiency and Reliability!

Benefits of Thermodynamic Steam Trap

| Compact Design | Robust Design | Reduce Maintenance Time | Effective Condensates Drainage |