Looking for FLUID LINE products and services?

Steam Separators: Importance and Function

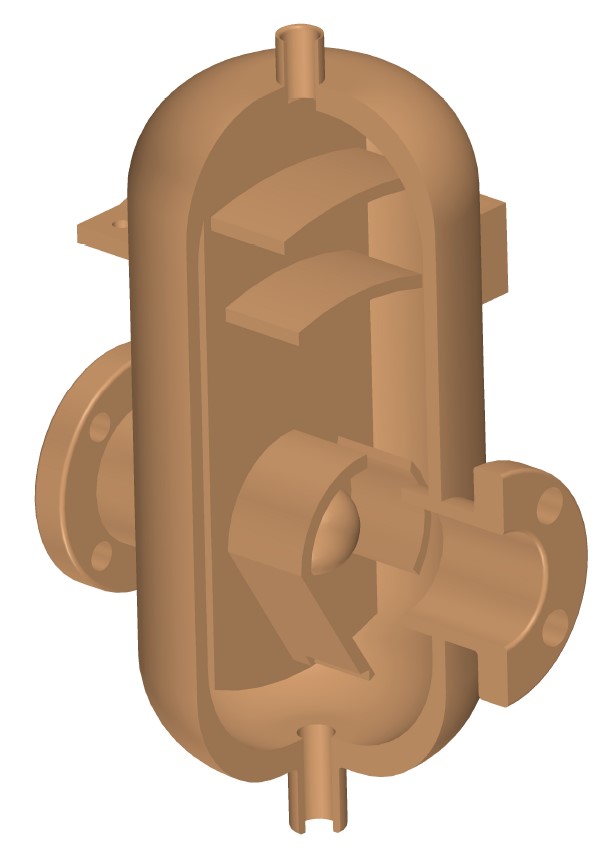

Steam Separators are essential components in steam systems used across various industries, including power plants, manufacturing facilities, and heating systems. The primary function of a Steam Separator is to remove moisture and other liquids from steam, ensuring the delivery of dry steam with high quality. This improves system efficiency and prevents damage caused by moisture or liquid contamination in the steam.

Key Functions of Steam Separators:

- Moisture Removal:

- Effectively separates water droplets and other liquids from steam.

- Dry Steam Production:

- Ensures the delivery of dry steam, which is critical for efficient heat transfer and system performance.

- Equipment Protection:

- Prevents damage to downstream equipment such as turbines, valves, and pipes caused by wet steam.

- Improved Efficiency:

- Enhances the overall efficiency of the steam system by providing high-quality steam.

How It Works:

- Steam Entry:

- Wet steam enters the separator through the inlet.

- Separation Process:

- The separator uses mechanisms such as centrifugal force, baffle plates, or mesh pads to separate moisture and liquids from the steam.

- Dry Steam Output:

- Dry steam exits the separator and is directed to the system for use.

- Liquid Drainage:

- The separated moisture and liquids are drained out of the system.

Benefits of Steam Separators:

- Enhanced System Performance:

- Improves heat transfer efficiency and system reliability.

- Equipment Longevity:

- Protects equipment from corrosion and erosion caused by wet steam.

- Energy Savings:

- Reduces energy losses by ensuring efficient steam usage.

- Cost Savings:

- Minimizes maintenance and repair costs by preventing moisture-related damage.

Applications:

- Power Plants: Ensures dry steam for turbines and other equipment.

- Industrial Processes: Suitable for industries such as food processing, chemicals, and pharmaceuticals.

- Heating Systems: Provides dry steam for efficient heating applications.

- Steam Distribution Systems: Protects pipelines and valves from moisture damage.

Why Choose Fluid Line for Steam Separators?

- Expertise: Extensive experience in designing and supplying steam separators for various industries.

- High-Quality Products: Separators are built to withstand high temperatures and pressures.

- Custom Solutions: Tailored to meet the specific needs of your steam system.

- Comprehensive Support: From selection and installation to maintenance and troubleshooting.

By incorporating Steam Separators into your steam system, you can ensure the delivery of high-quality dry steam, improving efficiency and protecting your equipment. If you need further details or assistance in selecting the right steam separator for your application, feel free to contact us!

Contact Us:

- Email: info@fluidline.net

- Phone: 085-6795642

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Steam System Efficiency and Reliability!

Benefits of steam separators

| Improve Steam Quality | Protect Plant Equipment |

| Document | Reference Number | Download |

| S1 Carbon Steel Separator | TI-01-0013 |