Looking for FLUID LINE products and services?

Fluid Line: Your Partner in High-Efficiency Industrial System Design and Development

Fluid Line is a company dedicated to designing and developing high-efficiency industrial systems to meet the needs of various industries, including oil and gas, food and beverage, and more. We have collaborated with numerous clients to deliver tailored and effective solutions.

Project Details: Pharmaceutical Industry

Project: Replacement of Fire Tubes in a Boiler

Client: A pharmaceutical manufacturing company located in Bang Pu

Project Scope: Boiler repair and upgrade

Project Overview:

- Objective:

- To replace damaged fire tubes in the boiler and improve its overall efficiency and reliability.

- Challenges:

- The boiler was experiencing reduced efficiency due to worn-out fire tubes.

- The client required minimal downtime to avoid disruptions in production.

- Solution:

- Fluid Line conducted a thorough inspection of the boiler and identified the need for fire tube replacement.

- We designed a customized solution to replace the fire tubes with high-quality, durable materials.

- The project was executed with precision to ensure minimal downtime and maximum efficiency.

- Outcome:

- The boiler’s efficiency was restored, resulting in significant energy savings.

- The client experienced no disruptions in production during the repair process.

- The upgraded boiler now operates reliably, meeting the client’s pharmaceutical manufacturing requirements.

Why Choose Fluid Line?

- Expertise: Extensive experience in designing and implementing industrial systems.

- Custom Solutions: Tailored solutions to meet the unique needs of each client.

- Efficiency: Focus on maximizing system performance and energy savings.

- Reliability: Commitment to delivering high-quality work with minimal downtime.

If you have a similar project or need assistance with your industrial systems, feel free to contact Fluid Line. We are here to provide innovative and efficient solutions for your business!

Contact Us:

- Phone: 085-6795642, 063-9984186

- Email: Nakhon@fluidline.net

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Industrial System Solutions!

Problem and Solution by Fluid Line

Problem:

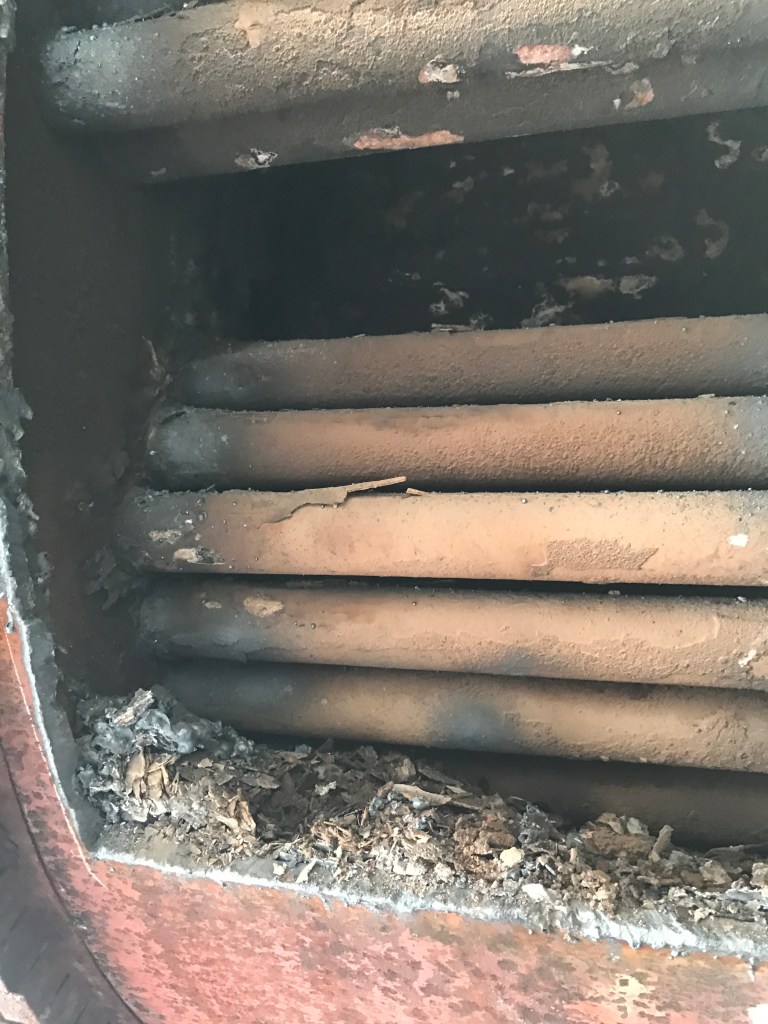

A boiler that had been in use for a long time experienced a significant drop in steam production efficiency. The flue gas temperature exceeded the specified limit, there were leaks in the fire tubes, and scale had accumulated inside nearly half of the boiler.

Fluid Line’s Solution:

- Cleaning and Replacing Fire Tubes:

- Planned to clean and replace all fire tubes within 3 days.

- After opening the boiler, it was found that scale buildup was so severe that the fire tubes could not be pulled out for replacement.

- Additional Solutions:

- Cut open the boiler wall to remove the fire tubes in shorter sections.

- Thoroughly cleaned the inside of the boiler.

- Replaced all fire tubes with new ones.

- Final Steps:

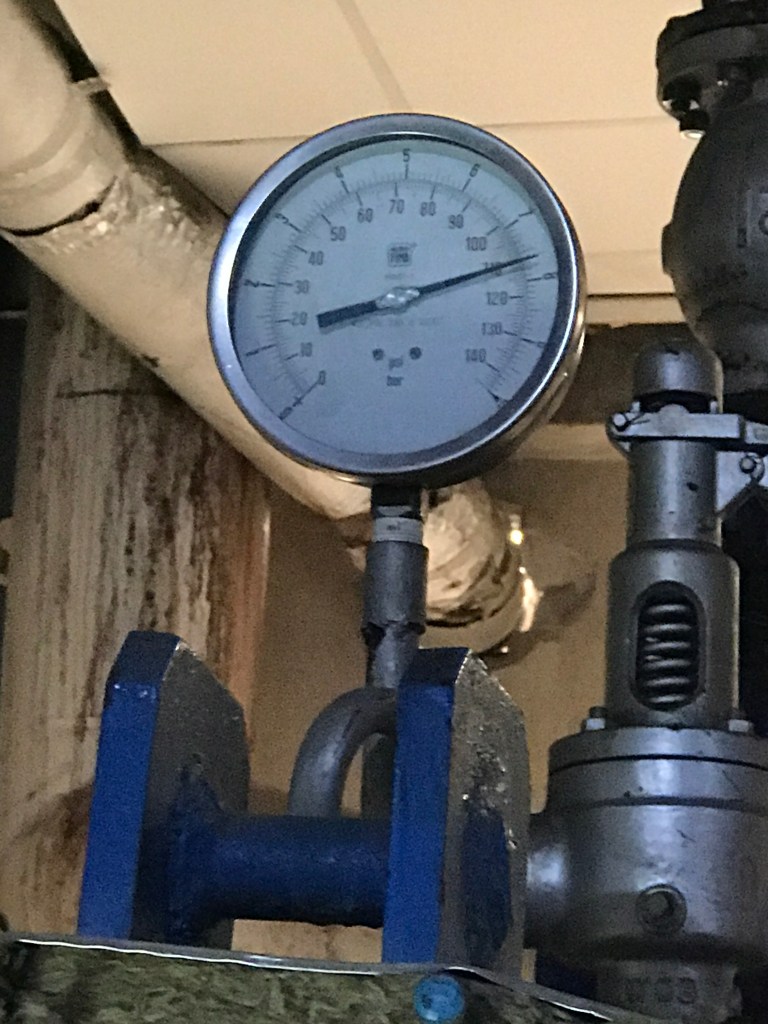

- Conducted pressure testing and safety inspections by engineers.

- Issued safety certification documents.

Results:

- The boiler’s steam production efficiency improved significantly.

- The flue gas temperature was reduced to within the specified limit.

- The system now operates efficiently and safely.

Conclusion:

Fluid Line successfully resolved the boiler issues within a limited timeframe using appropriate and effective methods. The customer achieved excellent results and gained confidence in the system’s safety.

If you are facing boiler or steam system issues, Fluid Line is ready to provide expert solutions to ensure your system operates efficiently and safely.

Contact Us:

- Phone: 085-6795642, 063-9984186

- Email: Nakhon@fluidline.net

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Steam and Thermal Energy Systems!

Project: Boiler System Upgrade for Animal Feed Industry

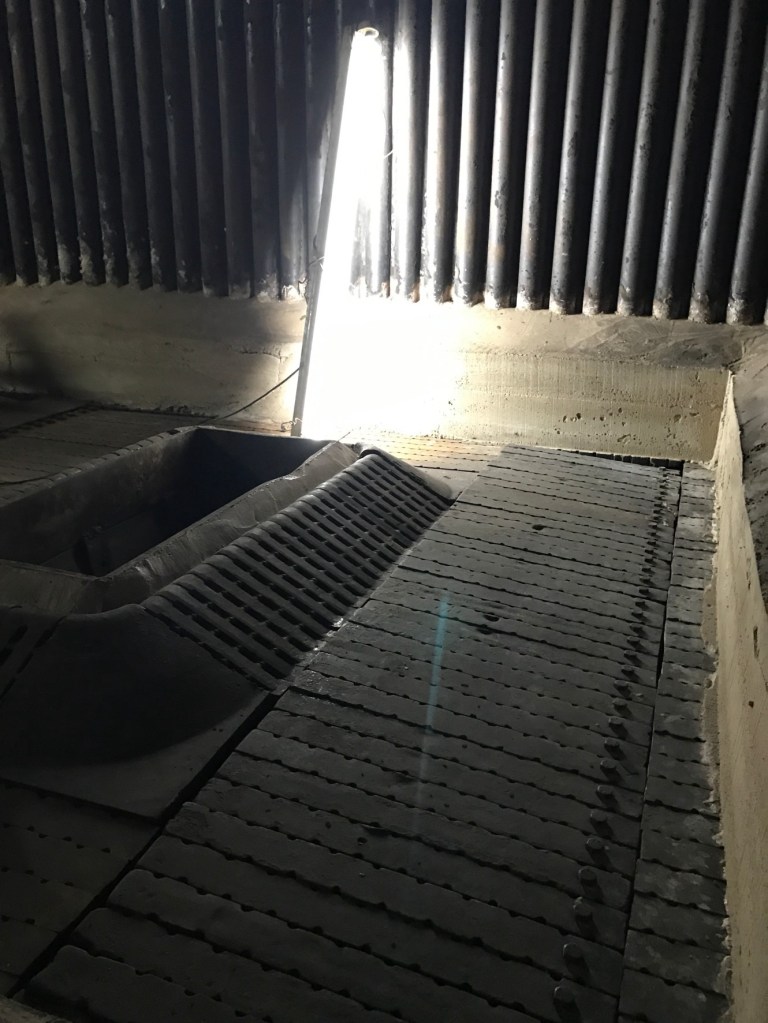

Project: Replacement of combustion chamber gratings and modification of the structure, including new ash hoppers for two 6-ton/hour boilers. Duration: 3 months.

Details:

- Designed and installed new ash hopper structures to handle ash disposal.

- Replaced all combustion chamber gratings with new ones.

- Applied new refractory lining inside the combustion chambers.

Results:

- Significantly improved boiler performance and efficiency.

- Reduced ash accumulation issues.

- Extended the lifespan of the equipment.

By upgrading the boiler system, Fluid Line ensured enhanced efficiency, reduced operational issues, and prolonged equipment life for the animal feed industry. If you need similar solutions for your industrial systems, feel free to contact us!

Contact Us:

- Phone: 085-6795642, 063-9984186

- Email: Nakhon@fluidline.net

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Industrial System Solutions!

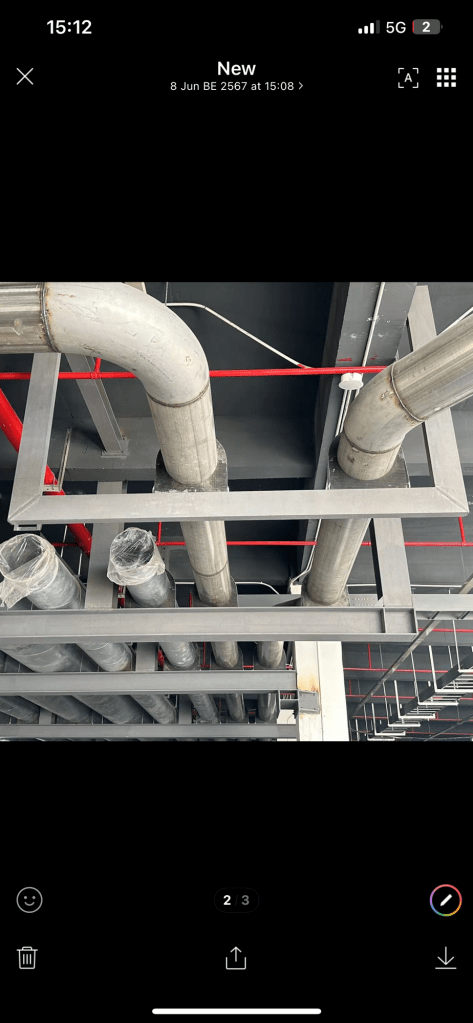

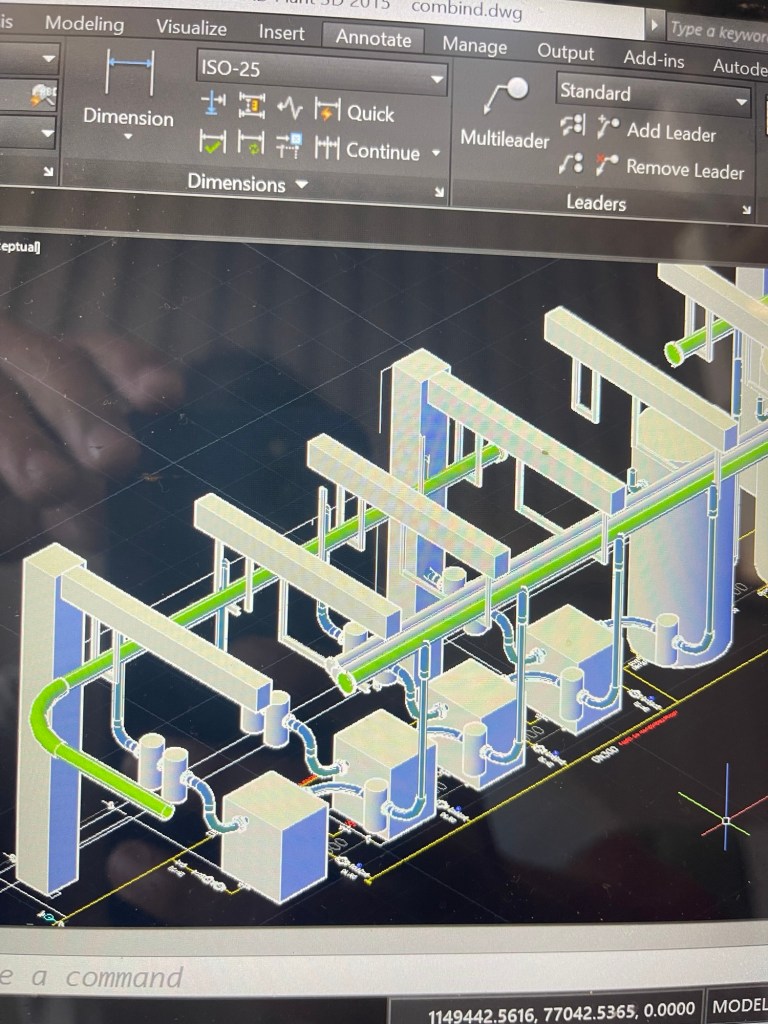

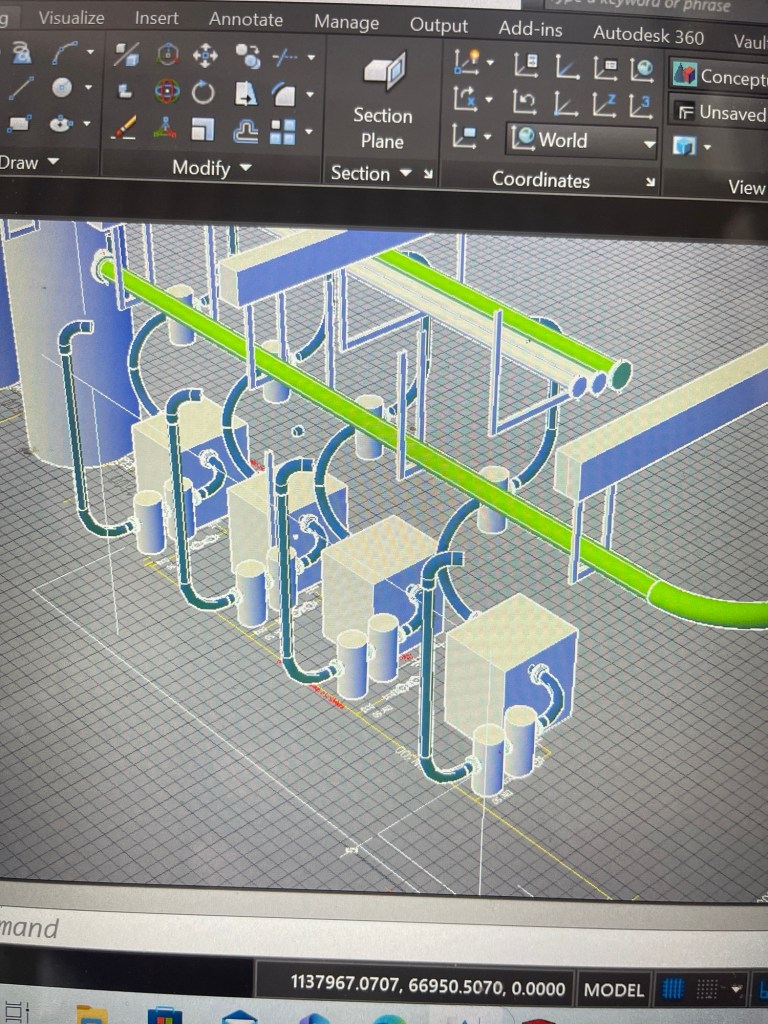

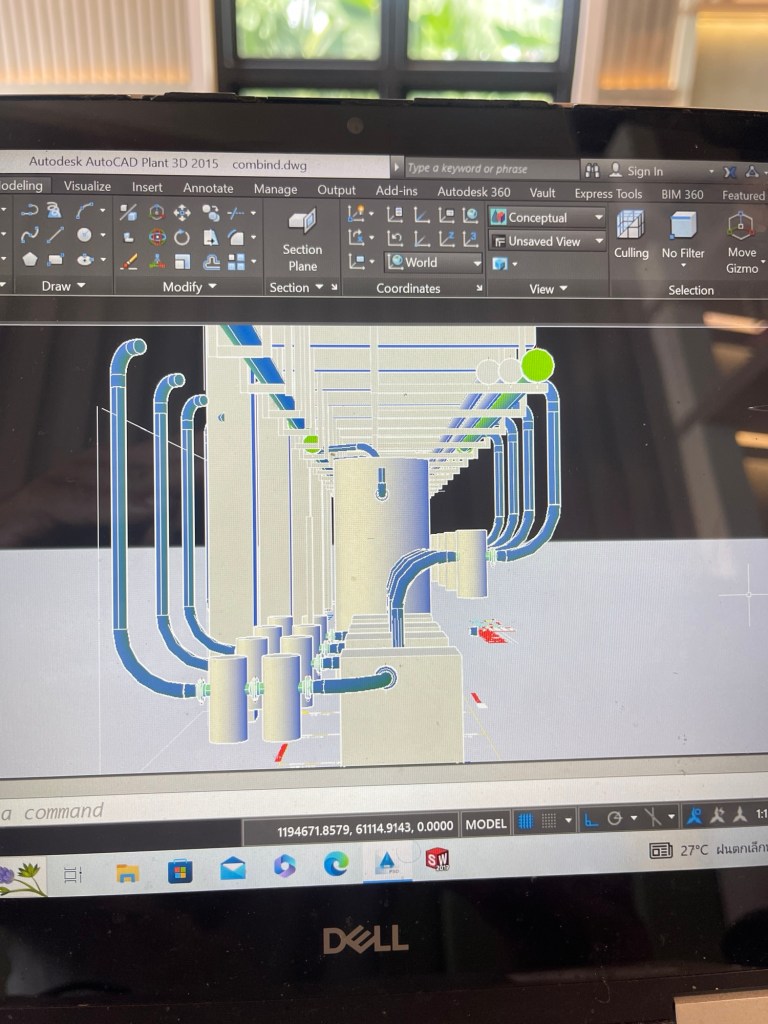

Project: Installation of a Comprehensive CDA (Clean Dry Air) System

Client: Sundell PCB Manufacturing Company, Rojana Industrial Park, Ayutthaya

Project: Installation of a complete CDA system with full equipment

Project Description:

Fluid Line was entrusted by the client to design and install a comprehensive Clean Dry Air (CDA) system to meet the industry’s demand for clean, dry, and highly efficient compressed air. The system includes state-of-the-art equipment from Ingersoll Rand and a water-cooled Cooling Tower system.

Project Details:

Main Equipment:

- Air Compressor: Installed 8 units of Ingersoll Rand air compressors.

- Air Dryer: Ensures the compressed air is free from moisture.

- Filtration System: Removes contaminants to deliver clean, dry air.

- Cooling Tower: Provides efficient cooling for the system.

- Piping and Distribution Network: Designed for optimal airflow and pressure.

Outcome:

- Delivered a reliable and efficient CDA system tailored to the client’s needs.

- Ensured clean, dry, and high-quality compressed air for PCB manufacturing processes.

- Improved production efficiency and product quality.

- Reduced downtime and maintenance costs.

Fluid Line’s expertise in designing and installing CDA systems ensures that your industrial processes run smoothly and efficiently. If you need similar solutions for your facility, feel free to contact us!

Contact Us:

- Phone: 085-6795642, 063-9984186

- Email: Nakhon@fluidline.net

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Industrial System Solutions!

Cooling Tower: Water-Based Cooling System

The Cooling Tower is a critical component of the Clean Dry Air (CDA) system, designed to maintain the system’s temperature at an optimal level. It uses water to dissipate heat, ensuring efficient and reliable operation of the entire system

Air Dryer: Ensuring Dry and Moisture-Free Compressed Air

As part of the Clean Dry Air (CDA) system, 8 Air Dryers were installed to ensure the compressed air is dry and free from moisture. This is critical for maintaining the efficiency and reliability of industrial processes, especially in industries like PCB manufacturing where moisture can cause significant issues.

Heat Recovery System: Maximizing Energy Efficiency

The Heat Recovery System is designed to capture and reuse waste heat generated during industrial processes, turning it into a valuable resource. This system not only improves energy efficiency but also reduces operational costs and environmental impact.

Air Separator and Air Filter: Ensuring Clean and Contaminant-Free Compressed Air

As part of the Clean Dry Air (CDA) system, Air Separators and Air Filters were installed to remove contaminants and separate particles from the compressed air. This ensures the delivery of clean, high-quality air, which is essential for sensitive industrial processed

Air Tank: Ensuring Stable Compressed Air Supply

As part of the Clean Dry Air (CDA) system, two 30,000-liter Air Tanks were installed to store compressed air and maintain stable pressure. These tanks play a crucial role in ensuring a consistent and reliable supply of compressed air for industrial processes.

Work Process: Installation of a Comprehensive CDA (Clean Dry Air) System

- Design the CDA System:

- Design the system to meet the customer’s requirements, focusing on efficiency and cost-effectiveness.

- Install Key Equipment:

- Install 8 Ingersoll Rand Air Compressors.

- Install a Cooling Tower to dissipate heat and maintain system temperature.

- Install 8 Air Dryers to ensure dry and moisture-free compressed air.

- Install a Heat Recovery System to reuse waste heat from the process.

- Install Air Separators and Air Filters to remove contaminants and particles from the compressed air.

- Install two 30,000-liter Air Tanks to store compressed air and maintain stable pressure.

- Connect Piping and Equipment:

- Connect all piping and equipment to ensure seamless and efficient operation.

- Test and Fine-Tune the System:

- Test the entire system to ensure optimal performance.

- Fine-tune the system for real-world application.

Results:

- Delivered clean, dry, and high-quality compressed air meeting industrial standards.

- Improved production efficiency by eliminating issues caused by moisture and contaminants.

- Achieved energy savings through the Heat Recovery System and Cooling Tower.

- Maintained stable compressed air pressure with large Air Tanks.

Conclusion:

With the design and installation of a comprehensive CDA system by Fluid Line, customers can trust that their compressed air system will operate efficiently, save energy, and meet industry standards.

If you need further information or consultation about CDA systems or other industrial solutions, feel free to contact us anytime.

Contact Us:

- Phone: 085-6795642, 063-9984186

- Email: Nakhon@fluidline.net

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Steam and Thermal Energy Systems!

Team and Technology:

Our team consists of experienced engineers specializing in compressed air systems and industrial equipment. We utilize state-of-the-art equipment and technology from Ingersoll Rand and other leading manufacturers to deliver top-quality solutions.

Contact Us:

Interested in a project or need more information? Contact Fluid Line at:

- Email: info@fluidline.net

- Phone: 085-6795642

Summary:

Fluid Line is committed to providing comprehensive CDA system design and installation services. With a team of professionals and high-quality equipment, we deliver superior performance and customer satisfaction in every project.

Fluid Line – Your Trusted Partner for Industrial System Solutions!

Project: Manufacturing Combustion Chambers for Solid Fuel Boilers

Project Description:

Fluid Line specializes in the design and manufacturing of combustion chambers for solid fuel boilers. These combustion chambers are engineered to optimize fuel efficiency, ensure reliable operation, and meet the specific needs of industrial and commercial boiler systems.

Key Features of the Combustion Chambers:

- High Efficiency:

- Designed to maximize fuel combustion efficiency, reducing fuel consumption and operational costs.

- Durable Construction:

- Built with high-quality, heat-resistant materials to withstand high temperatures and harsh operating conditions.

- Customizable Design:

- Tailored to meet the specific requirements of your boiler system and fuel type.

- Eco-Friendly:

- Optimized for clean combustion, minimizing emissions and environmental impact.

- Easy Maintenance:

- Designed for easy access and maintenance, ensuring long-term reliability.

Applications:

- Industrial Boilers: Suitable for industries such as food processing, textiles, and chemicals.

- Power Plants: Ensures efficient combustion in solid fuel-based power generation.

- Heating Systems: Ideal for district heating or large-scale heating applications.

- Biomass Boilers: Compatible with renewable solid fuels like wood chips, pellets, and agricultural waste.

Benefits of Fluid Line’s Combustion Chambers:

- Improved Boiler Performance:

- Enhances combustion efficiency, leading to better heat transfer and energy output.

- Cost Savings:

- Reduces fuel consumption and operational costs.

- Environmental Compliance:

- Meets emission standards by promoting clean and efficient combustion.

- Long Service Life:

- Durable construction ensures reliable operation over the long term.

Why Choose Fluid Line?

- Expertise: Years of experience in designing and manufacturing combustion systems.

- Custom Solutions: Tailored designs to meet your specific boiler and fuel requirements.

- Quality Assurance: High-quality materials and rigorous testing ensure reliable performance.

- Comprehensive Support: From design and manufacturing to installation and maintenance.

If you are looking for a reliable partner to design and manufacture combustion chambers for solid fuel boilers, contact Fluid Line today!

Contact Us:

- Email: info@fluidline.net

- Phone: 085-6795642

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Industrial Boiler Solutions!

Project: Solid Fuel Boiler for Betago Company, Saraburi

Project Description:

Fluid Line was entrusted by Betago Company in Saraburi to design, manufacture, and install a solid fuel boiler tailored to their specific industrial needs. This project involved delivering a high-efficiency boiler system capable of handling solid fuels such as biomass, wood chips, or coal, ensuring reliable and cost-effective operation.

Key Features of the Solid Fuel Boiler:

- High Efficiency:

- Optimized combustion design to maximize fuel efficiency and heat output.

- Durable Construction:

- Built with high-quality, heat-resistant materials to withstand high temperatures and harsh operating conditions.

- Eco-Friendly Operation:

- Designed for clean combustion, minimizing emissions and environmental impact.

- Customizable Design:

- Tailored to meet Betago’s specific fuel type and operational requirements.

- Easy Maintenance:

- Designed for easy access and maintenance, ensuring long-term reliability.

Scope of Work:

- Design and Engineering:

- Customized design to meet Betago’s fuel type, capacity, and operational needs.

- Manufacturing:

- Fabrication of the boiler and combustion chamber using high-quality materials.

- Installation:

- Professional installation and integration with existing systems.

- Testing and Commissioning:

- Thorough testing to ensure optimal performance and safety.

- Training and Support:

- Provided training for Betago’s staff and ongoing technical support.

Benefits of the Solid Fuel Boiler:

- Cost Savings:

- Reduced fuel consumption and operational costs due to high combustion efficiency.

- Environmental Compliance:

- Clean combustion technology minimizes emissions and supports sustainability.

- Reliable Operation:

- Ensures consistent performance for Betago’s industrial processes.

- Long Service Life:

- Durable construction and high-quality materials ensure long-term reliability.

Why Choose Fluid Line?

- Expertise: Extensive experience in designing and manufacturing solid fuel boilers.

- Custom Solutions: Tailored designs to meet specific industrial requirements.

- Quality Assurance: High-quality materials and rigorous testing ensure reliable performance.

- Comprehensive Support: From design and manufacturing to installation and maintenance.

By partnering with Fluid Line, Betago Company received a solid fuel boiler that meets their operational needs, improves efficiency, and supports their sustainability goals.

If you are looking for a reliable partner to design and install a solid fuel boiler or other industrial solutions, contact Fluid Line today!

Contact Us:

- Email: info@fluidline.net

- Phone: 085-6795642

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Industrial Boiler Solutions!