Looking for FLUID LINE products and services?

Product

Welcome to Fluid Line, Your Expert in Comprehensive Steam Systems and Heat Recovery Solutions!

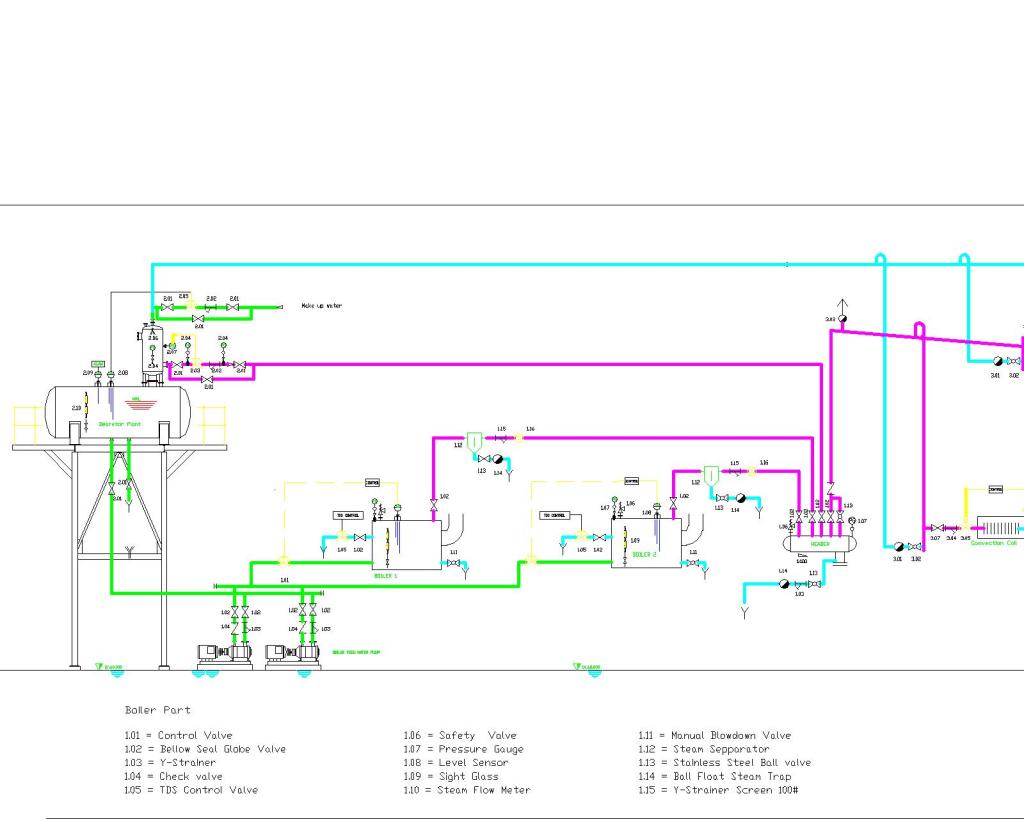

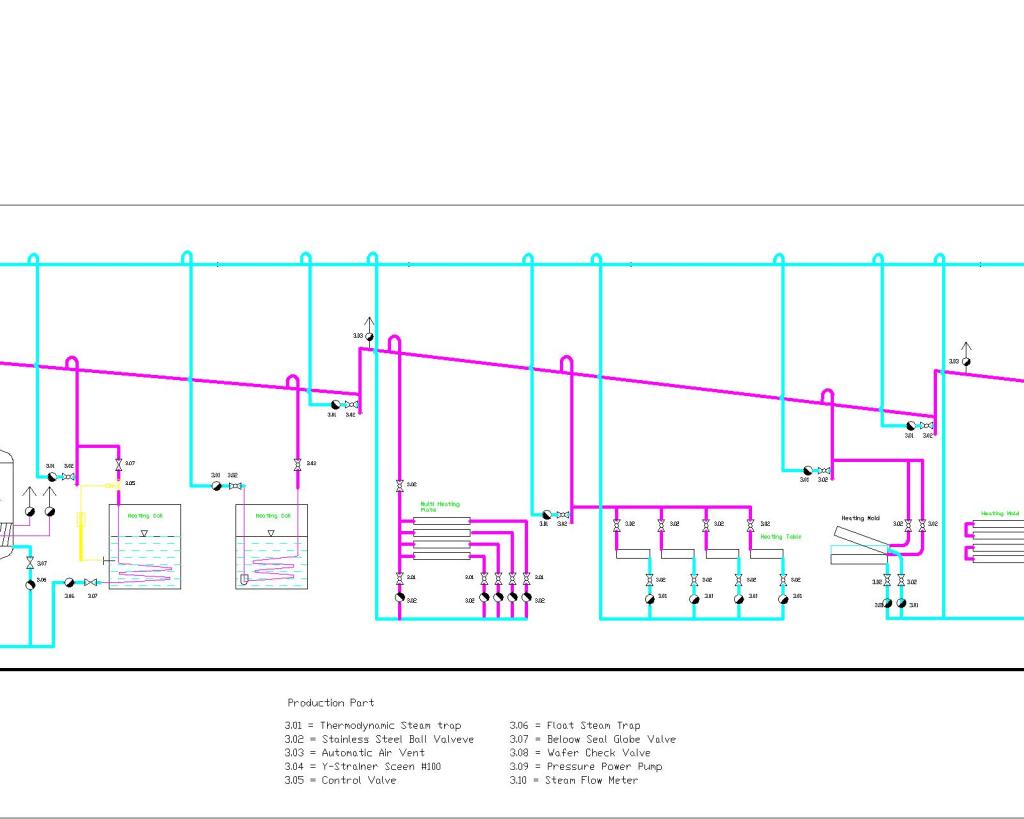

We are committed to providing state-of-the-art products and solutions to enhance efficiency and energy savings in your production processes. Whether you are looking for Steam Trap Valves, Heat Recovery Systems, or Steam Pipe Accessories, we have everything you need

1. Steam Trap

A Steam Trap is an essential device in steam systems, designed to remove condensate (water formed from condensed steam), air, and non-condensable gases from the system without allowing steam to escape.

By using a Steam Trap, you can ensure efficient steam system operation, reduce energy waste, and extend the lifespan of your equipment. If you need further assistance in selecting the right steam trap for your application, feel free to contact us!

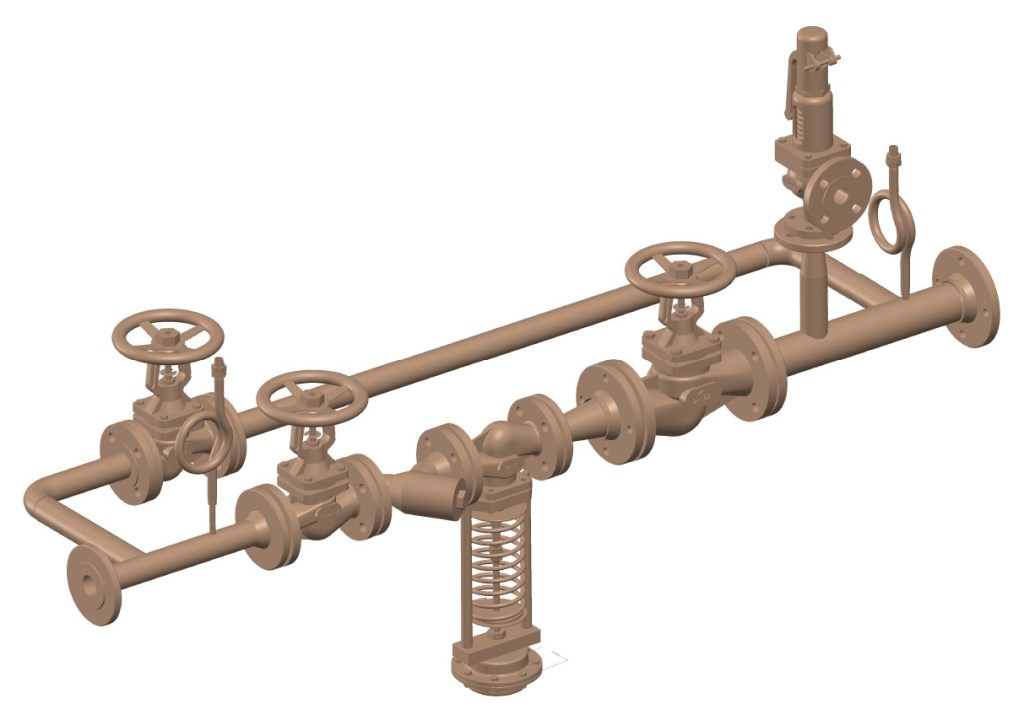

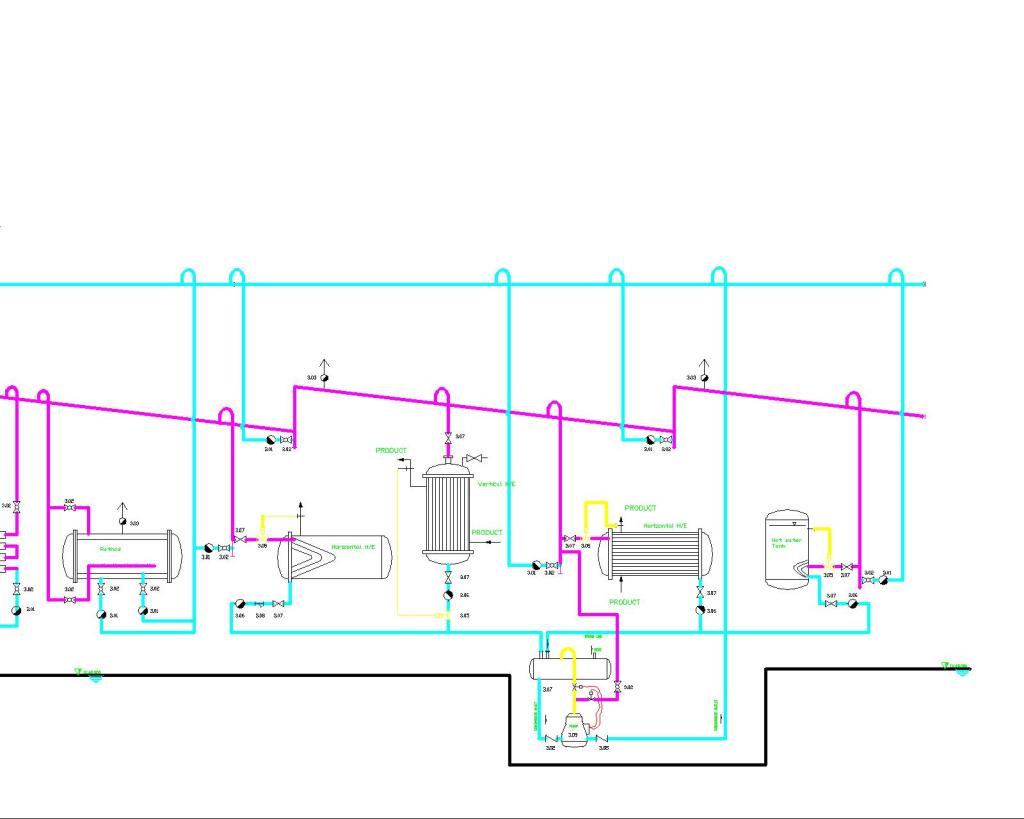

2. Heat Recovery System

Our Heat Recovery System is designed to capture and reuse waste heat generated during industrial processes, significantly improving energy efficiency and reducing production costs.

By implementing our Heat Recovery System, you can optimize energy usage, reduce waste, and enhance the sustainability of your operations. If you need more information or a customized solution, feel free to reach out to us!

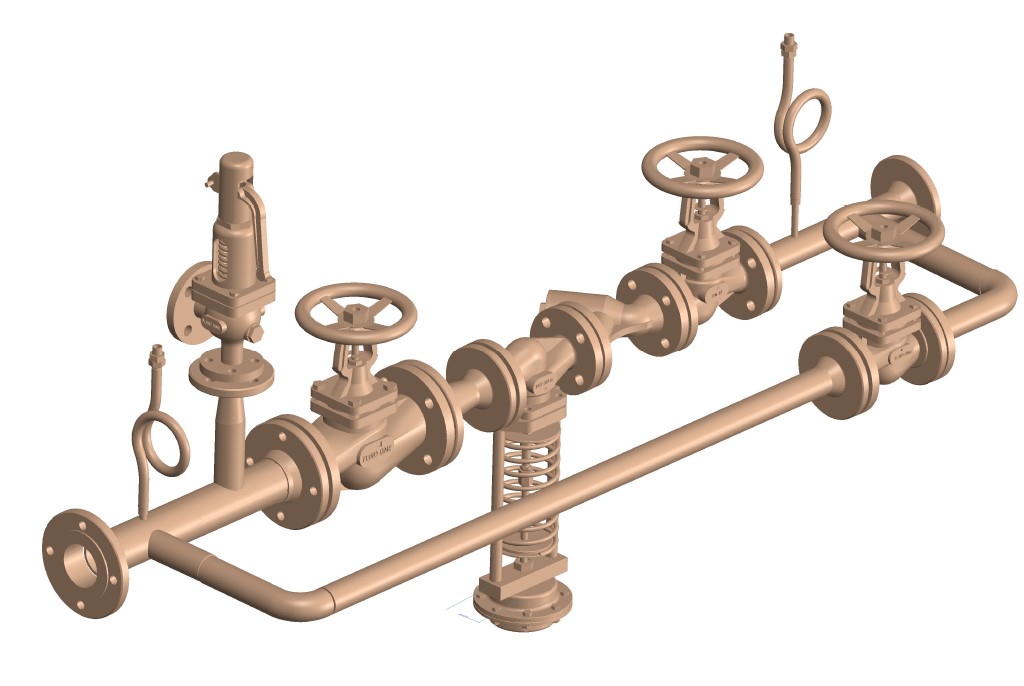

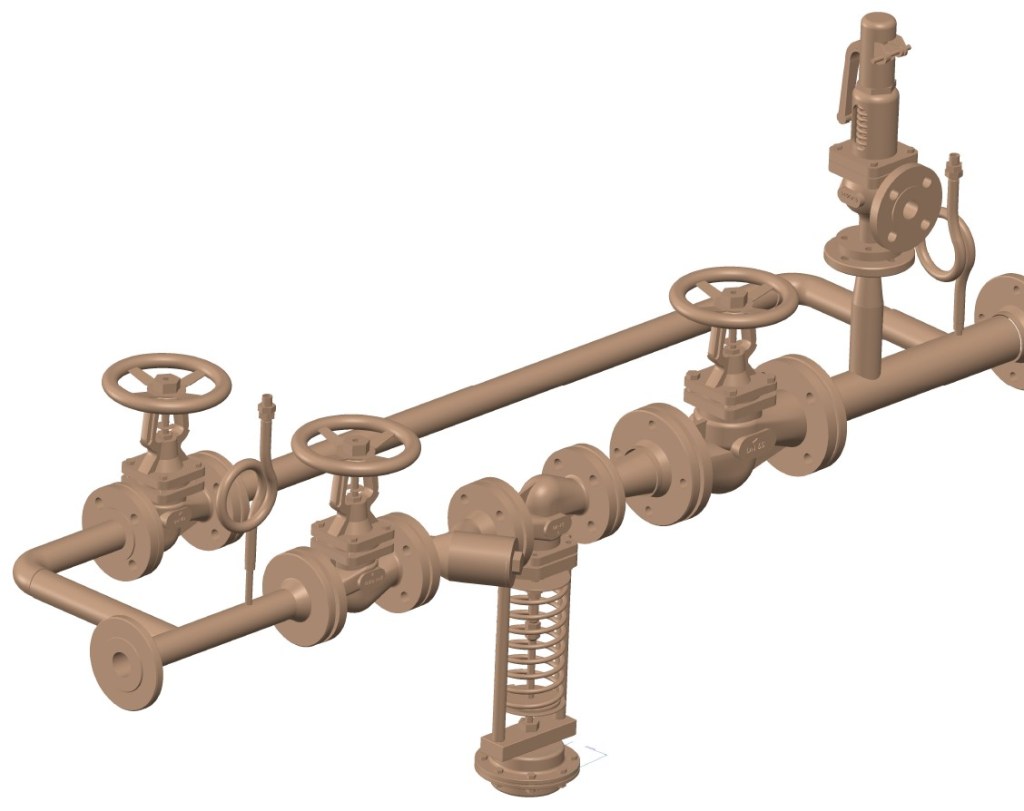

3. Steam Pipe Accessories

We provide a comprehensive range of accessories for steam pipe systems to ensure efficient and safe operation.

Our Steam Pipe Accessories are designed to enhance the performance, safety, and efficiency of your steam systems. If you need further details or assistance in selecting the right products, feel free to contact us!

Why Choose Fluid Line?

- High Quality: Our products are tested and certified to meet international standards.

- Comprehensive Services: From consultation and design to installation and maintenance.

- Energy Savings: Helps reduce production costs and improve energy efficiency.

- Professional Team: Ready to provide expert advice and full support.

Contact Us

If you need more information or consultation about our products, the Fluid Line team is ready to assist you every day.

- Phone: 085-6795642, 063-9984186

- Email: Nakhon@fluidline.net

- Website: http://www.fluidline.net

Fluid Line – Your Trusted Partner for Steam and Thermal Energy Systems!

Steam Trap

Thermodynamic Steam Trap

The Thermodynamic Steam Trap is a highly efficient and reliable device designed to discharge condensate with precision. Known for its simplicity and high performance, it features only one moving part—a hardened stainless steel disc. This design makes it highly resistant to superheated steam, water hammer, condensate, and vibrations.

The Thermodynamic Steam Trap is a top choice for ensuring efficient condensate removal and maintaining the optimal performance of your steam system. If you need further details or assistance in selecting the right steam trap for your application, feel free to contact us!

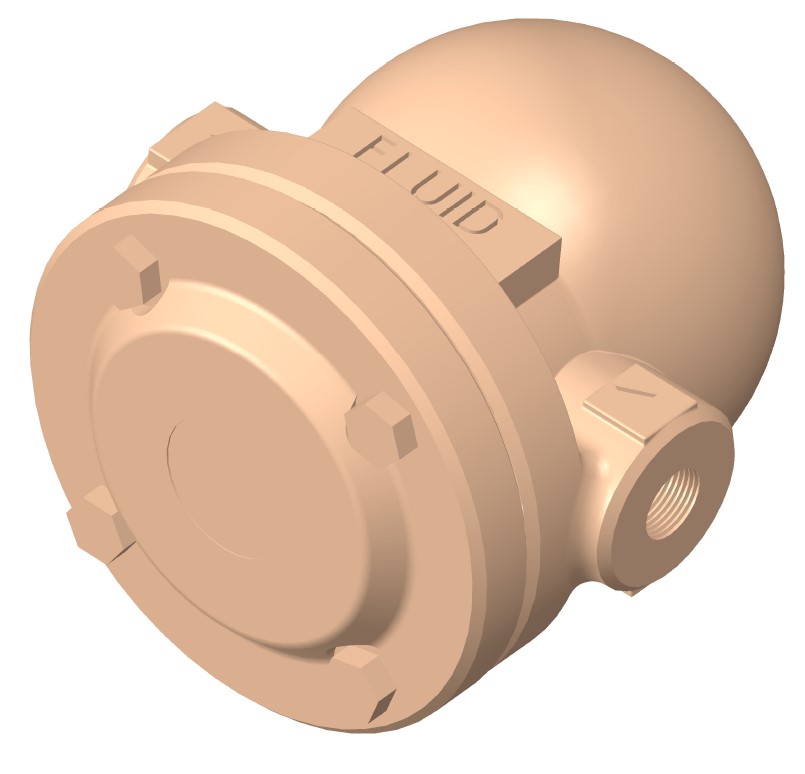

Ball Float Steam Trap

The Ball Float Steam Trap is a highly versatile and efficient device designed to handle both low and high condensate loads. Its compact design, combined with its ability to provide continuous and high-capacity condensate discharge, ensures maximum heat transfer efficiency in your equipment.

The Ball Float Steam Trap is an excellent choice for efficient condensate removal, ensuring your system operates at peak performance. If you need further details or assistance in selecting the right steam trap for your application, feel free to contact us!

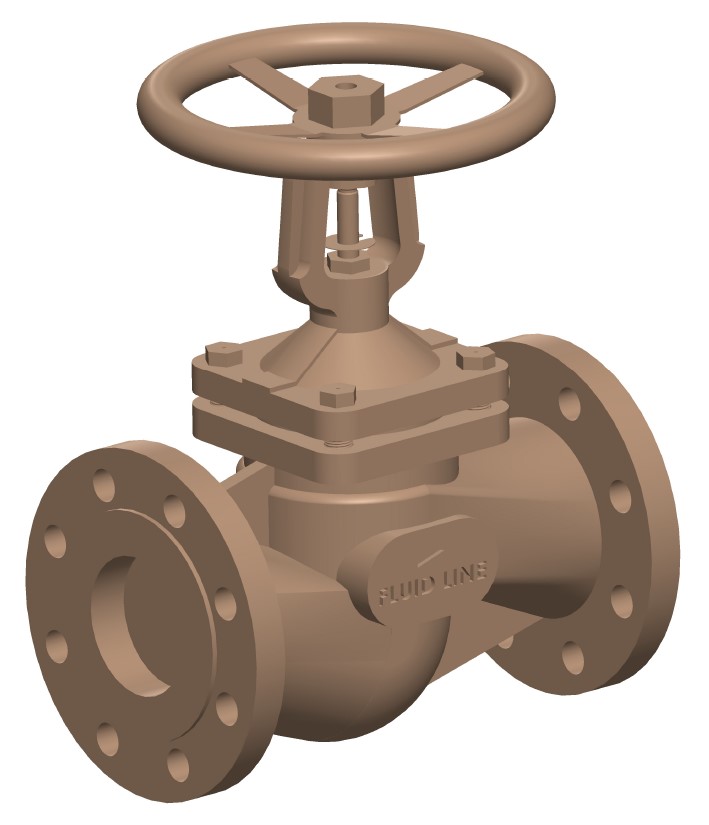

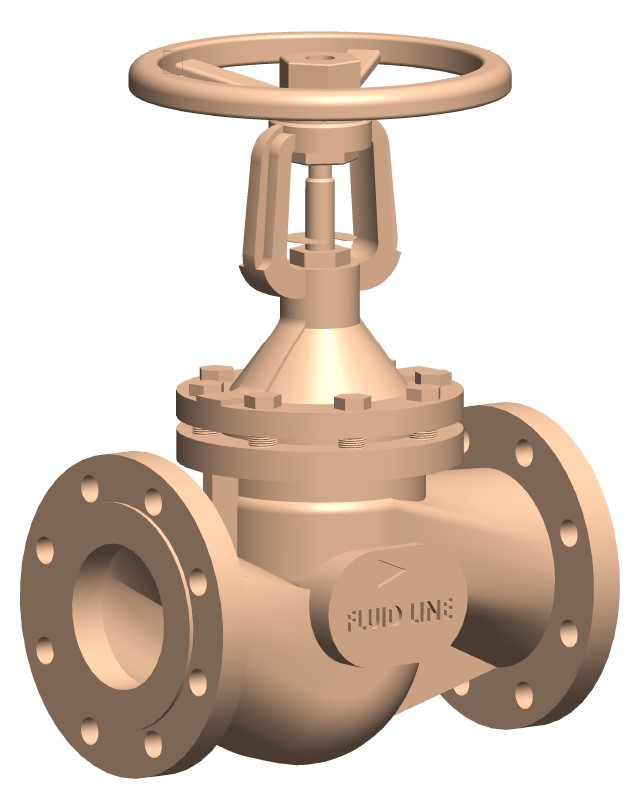

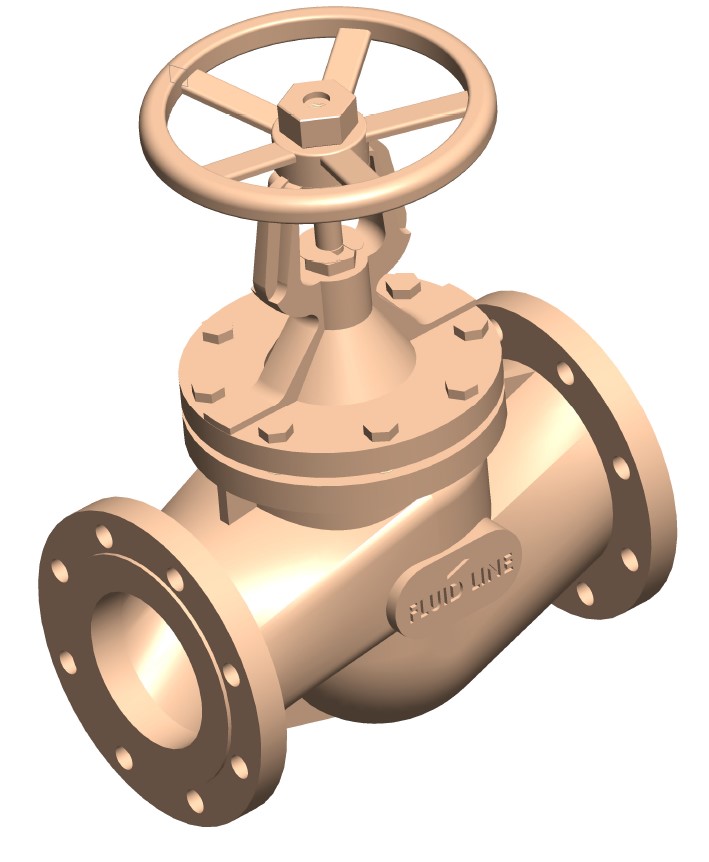

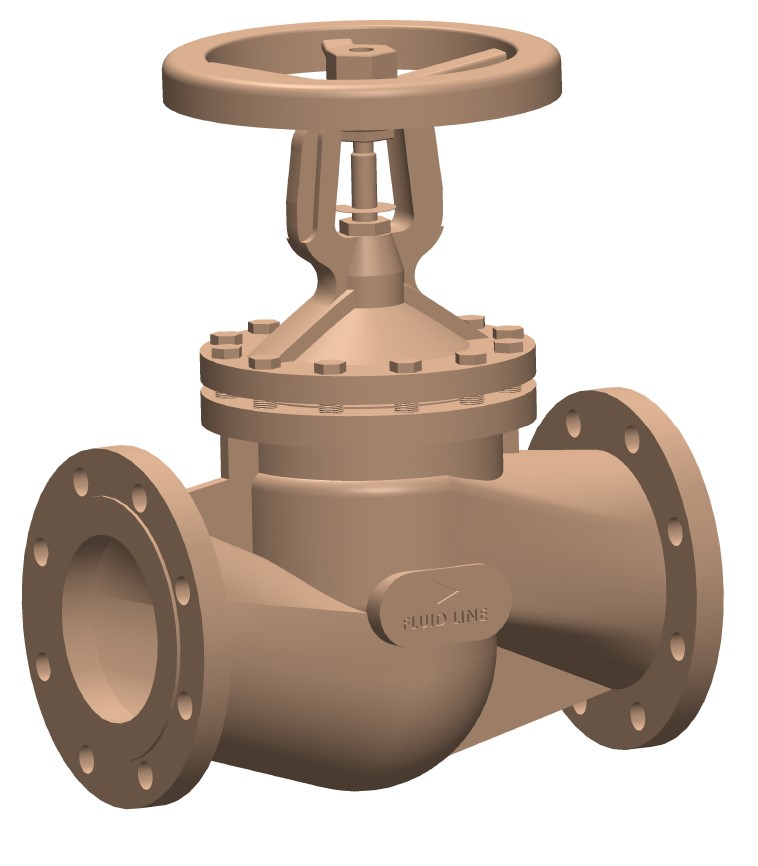

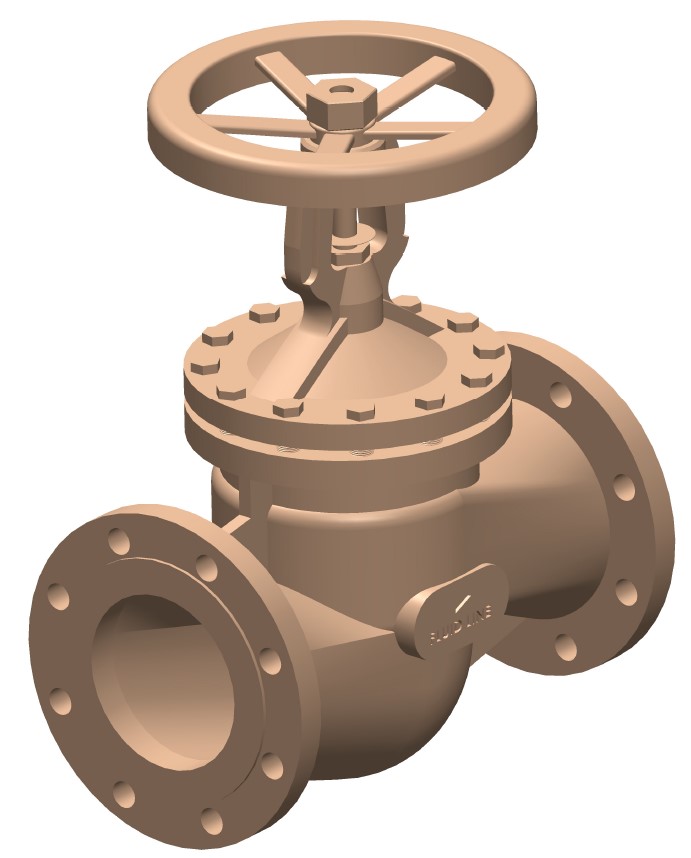

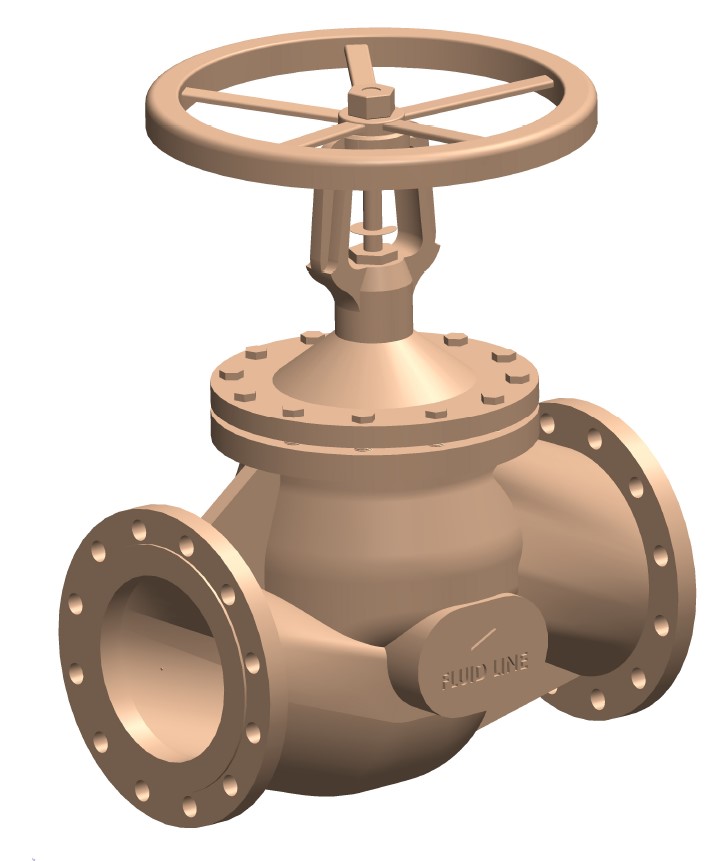

Bellow Seal Globe Valve

The Bellow Seal Globe Valve is the best choice for environmentally friendly steam shut-off applications. Its hermetically sealed bellows design ensures zero stem seal leakage, complying with the most stringent global emission regulations. This valve is essential for environmental protection, energy savings, and promoting a cleaner environment, guaranteeing zero emissions.The Bellow Seal Globe Valve is a reliable and environmentally friendly solution for your steam system needs. If you need further details or assistance in selecting the right valve for your application, feel free to contact us!

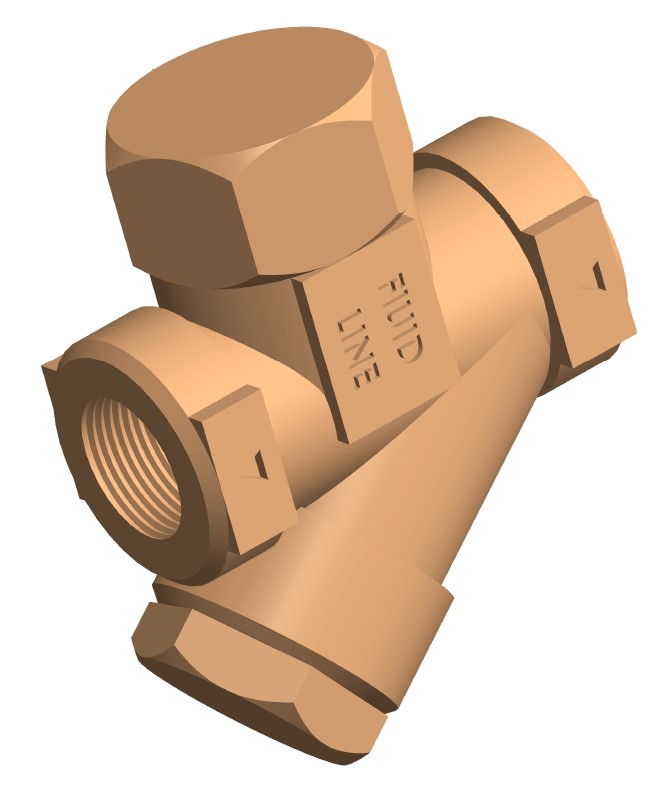

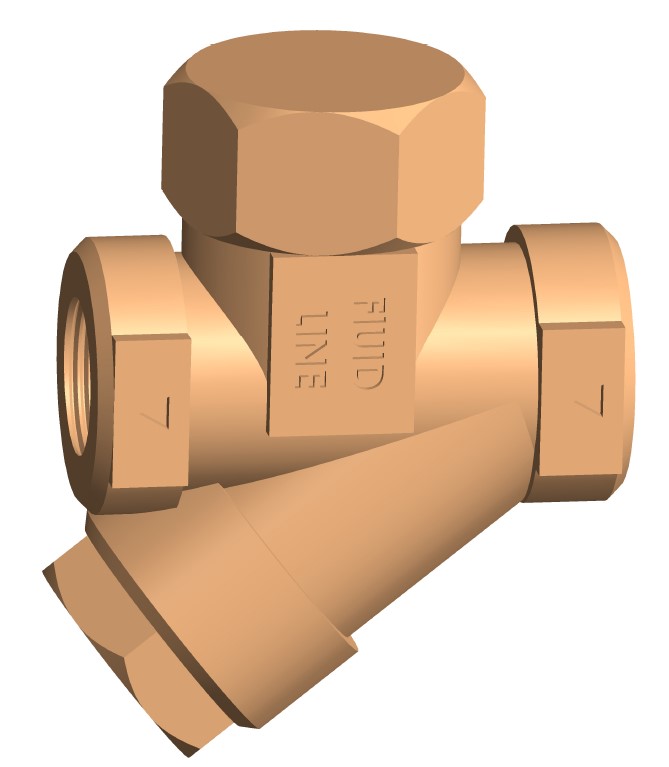

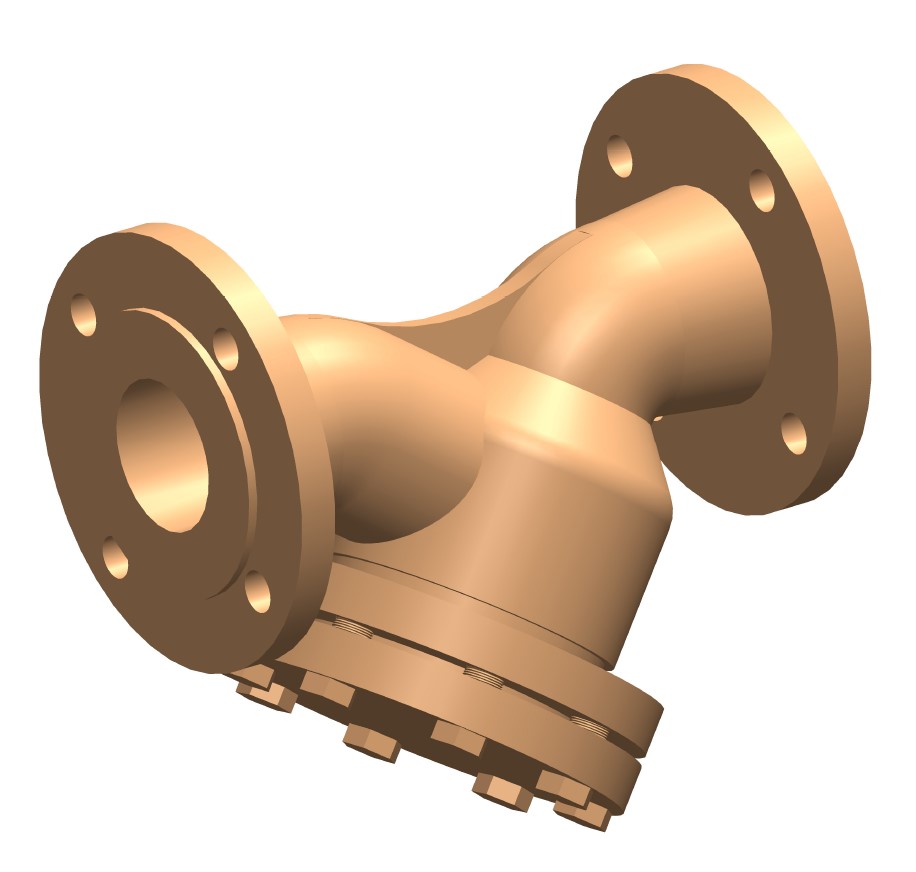

Y-Strainer

The Y-Strainer is a high-efficiency steam filter designed to improve steam quality by removing impurities from the steam supply. It effectively reduces contamination levels, ensuring the quality of the final product.By incorporating a Y-Strainer into your steam system, you can ensure the delivery of clean, high-quality steam, which is essential for optimal performance and protection of your equipment. If you need further details or assistance in selecting the right strainer for your application, feel free to contact us!

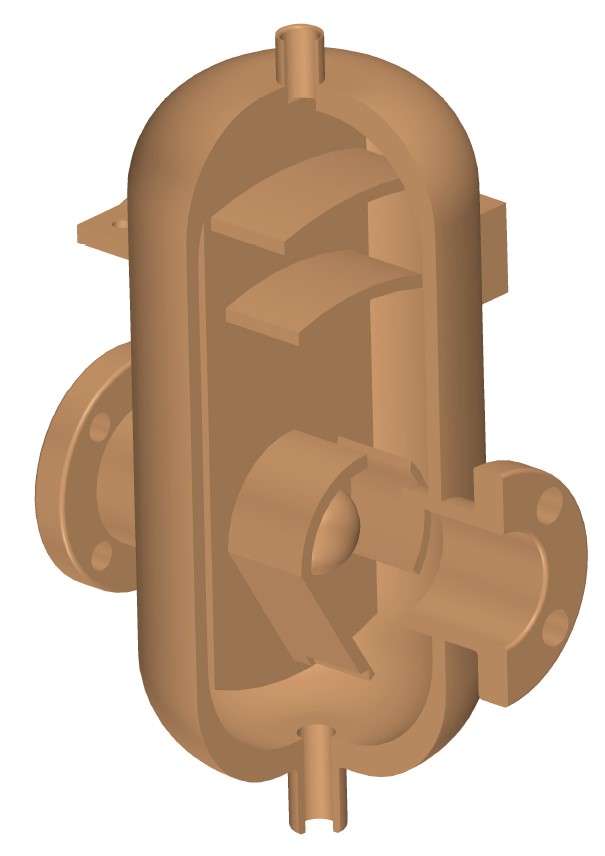

Steam Separator

Steam Separators are designed to collect and remove fine water droplets from steam, separating them from the steam flow. This process reduces wet steam, maintains heat transfer efficiency, minimizes corrosion in your steam system, and reduces the size of piping and heating surfaces required.By incorporating a Steam Separator into your steam system, you can ensure the delivery of dry, high-quality steam, which is essential for optimal performance and longevity of your equipment. If you need further details or assistance in selecting the right separator for your application, feel free to contact us!

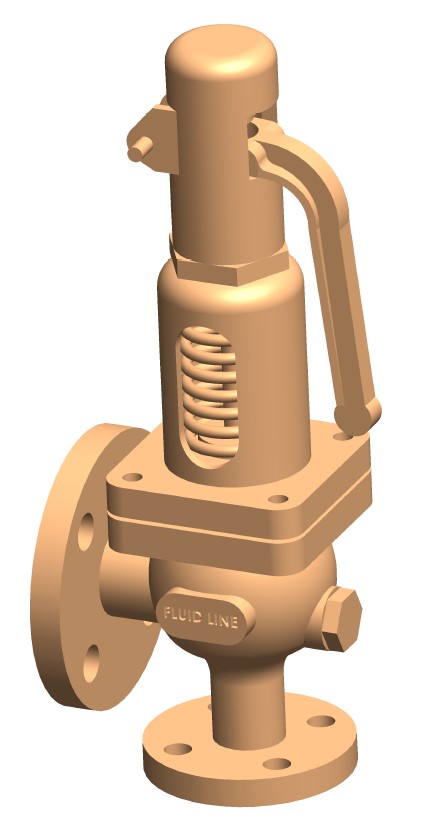

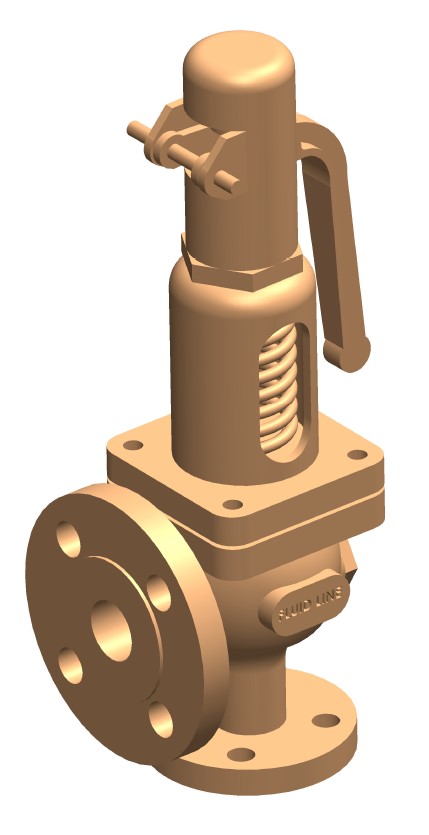

Safety Valve

Safety Valves are crucial in any system where dangerous overpressure situations may occur. They provide essential protection by:By installing a Safety Valve, you can ensure the safe and reliable operation of your system, protecting both equipment and personnel. If you need further details or assistance in selecting the right safety valve for your application, feel free to contact us!

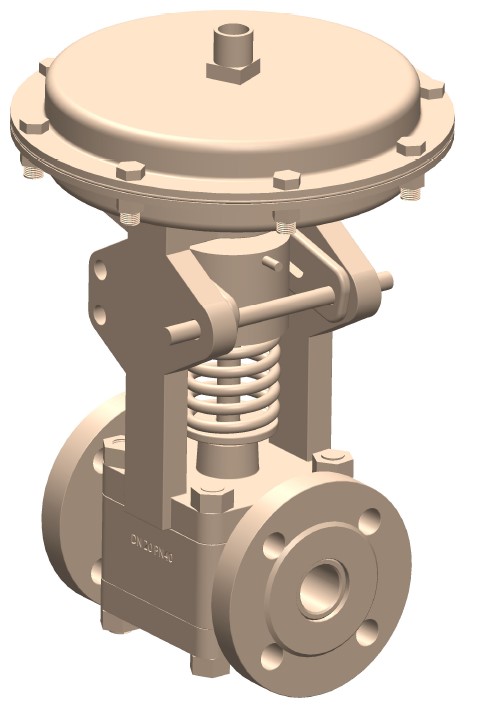

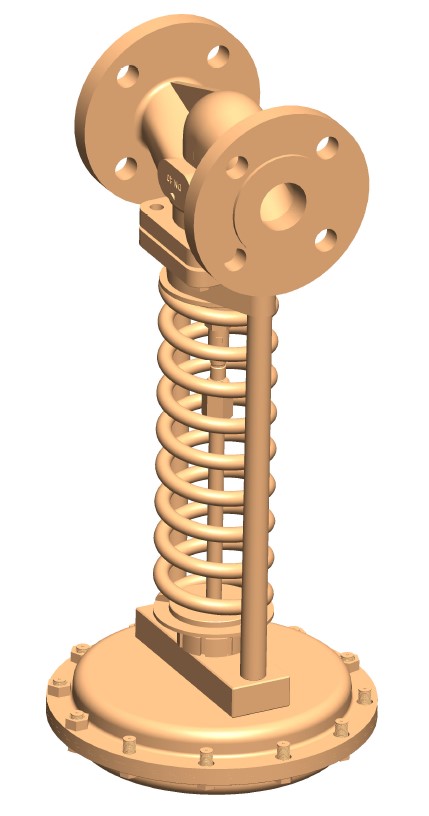

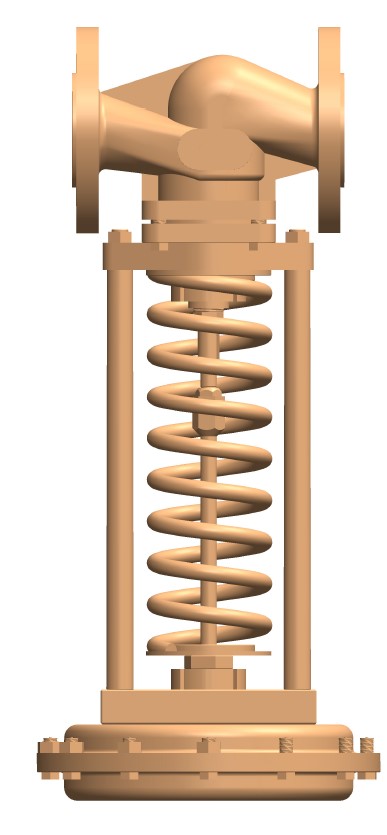

Direct Acting Pressure Reducing Valve

The Direct Acting Pressure Reducing Valve is a well-designed valve for reducing pressure in steam systems, delivering dry and clean steam at lower pressures. It ensures the highest quality steam at the lowest cost. Typically, low-pressure steam is required at the point of use, and efficient control is achieved through automatic control valves that precisely and reliably reduce steam pressure at an affordable cost. These valves are self-operating (do not require external power) and can be controlled using pneumatic signals or actuators.By using a Direct Acting Pressure Reducing Valve, you can achieve optimal steam quality and pressure control, ensuring efficient and cost-effective operation of your steam system. If you need further details or assistance in selecting the right valve for your application, feel free to contact us!

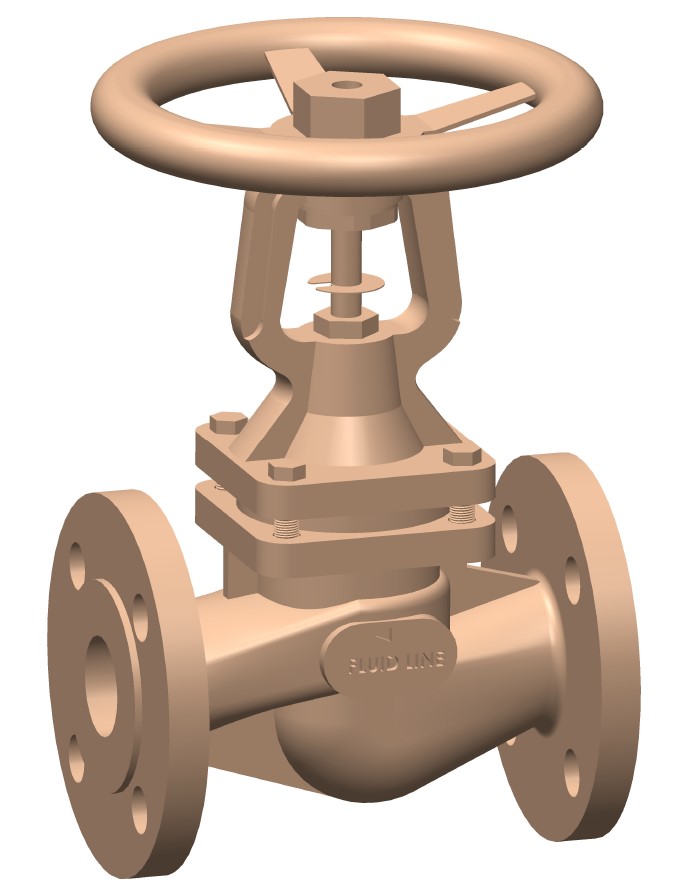

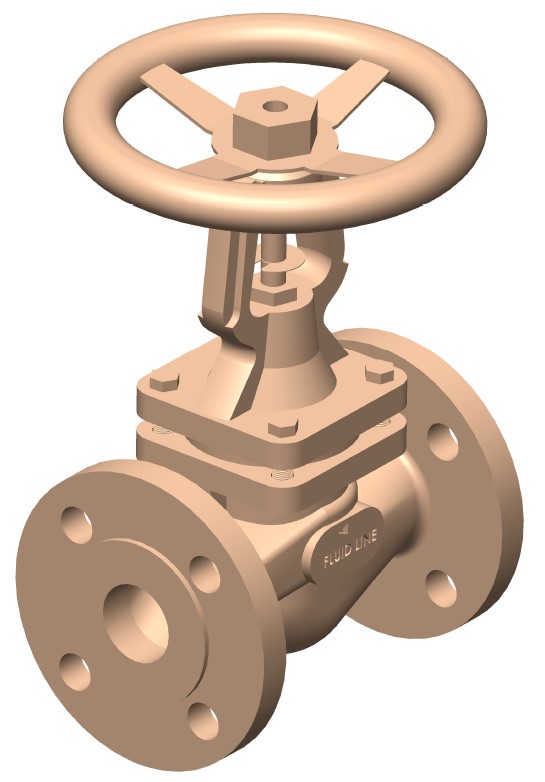

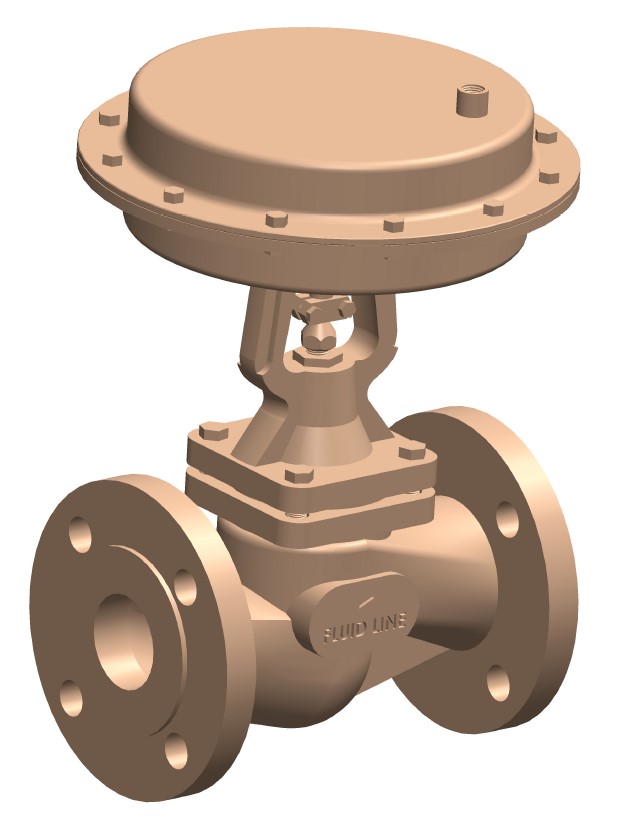

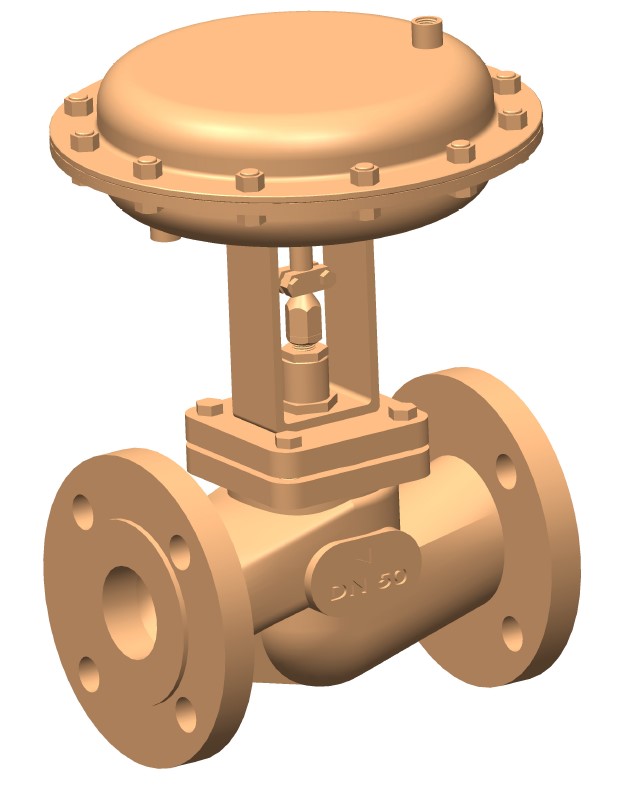

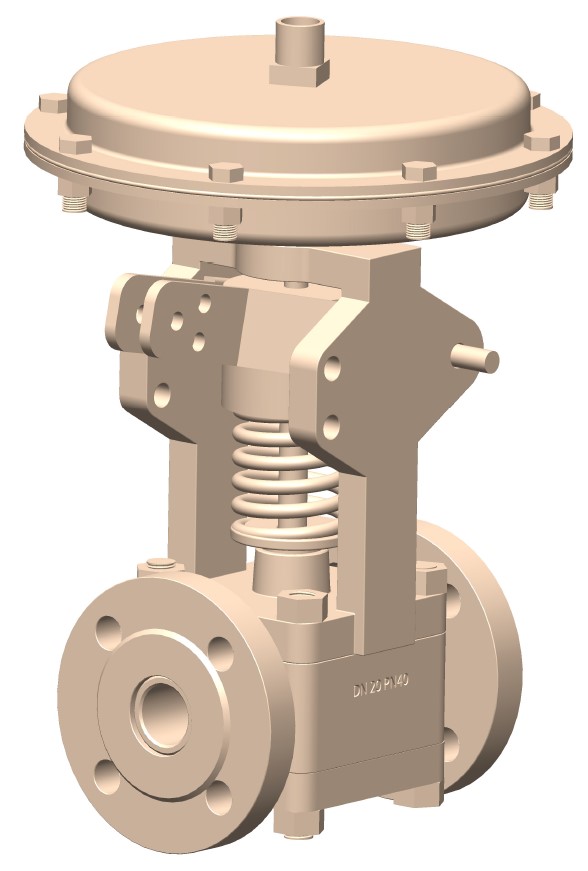

Control Valve

The Control Valve is a versatile valve used to regulate temperature, pressure, and flow rate of steam, providing comprehensive control to meet all application requirements. By incorporating a Control Valve into your steam system, you can achieve optimal performance, efficiency, and reliability. If you need further details or assistance in selecting the right control valve for your application, feel free to contact us!

Automatic Blowdown Valve

Efficient boiler blowdown (removal of impurities from the boiler) is essential for maintaining steam quality. The Automatic Blowdown Valve is designed for precise and consistent removal of settled solids from the bottom of the boiler. It is available in both manual and fully automatic systems.By using an Automatic Blowdown Valve, you can ensure the efficient removal of impurities, maintaining high steam quality and prolonging the lifespan of your boiler system. If you need further details or assistance in selecting the right blowdown valve for your application, feel free to contact us!

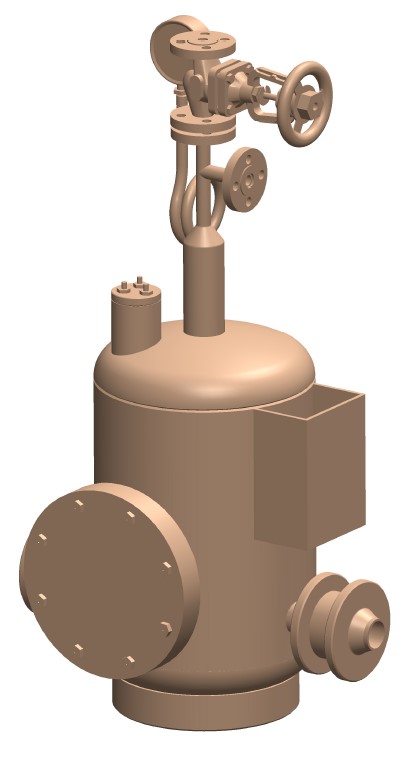

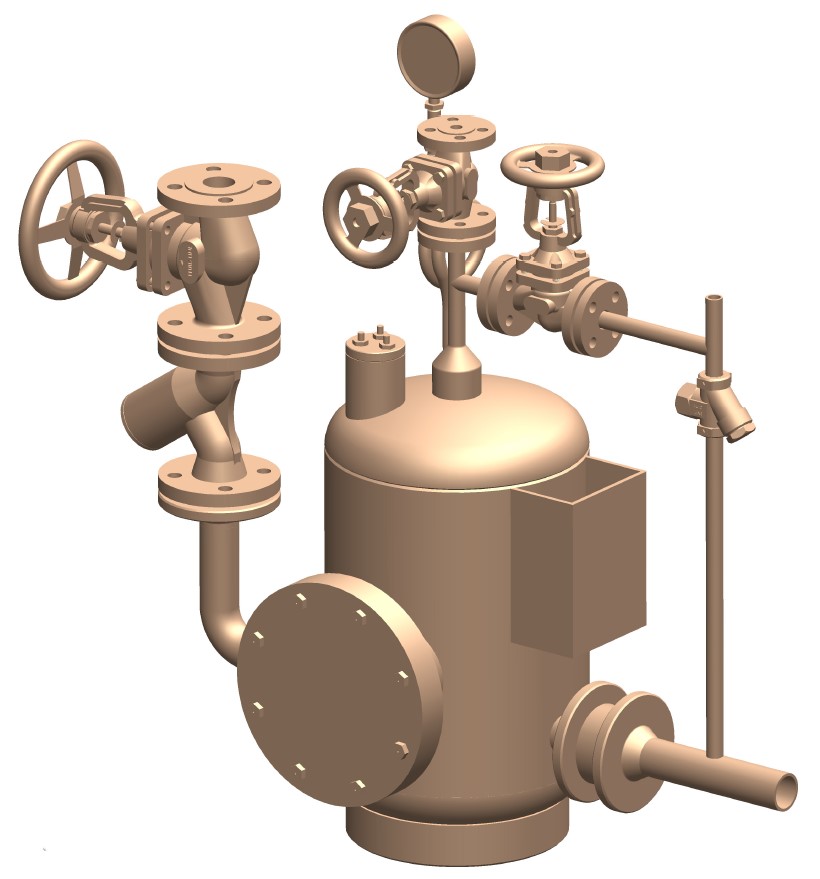

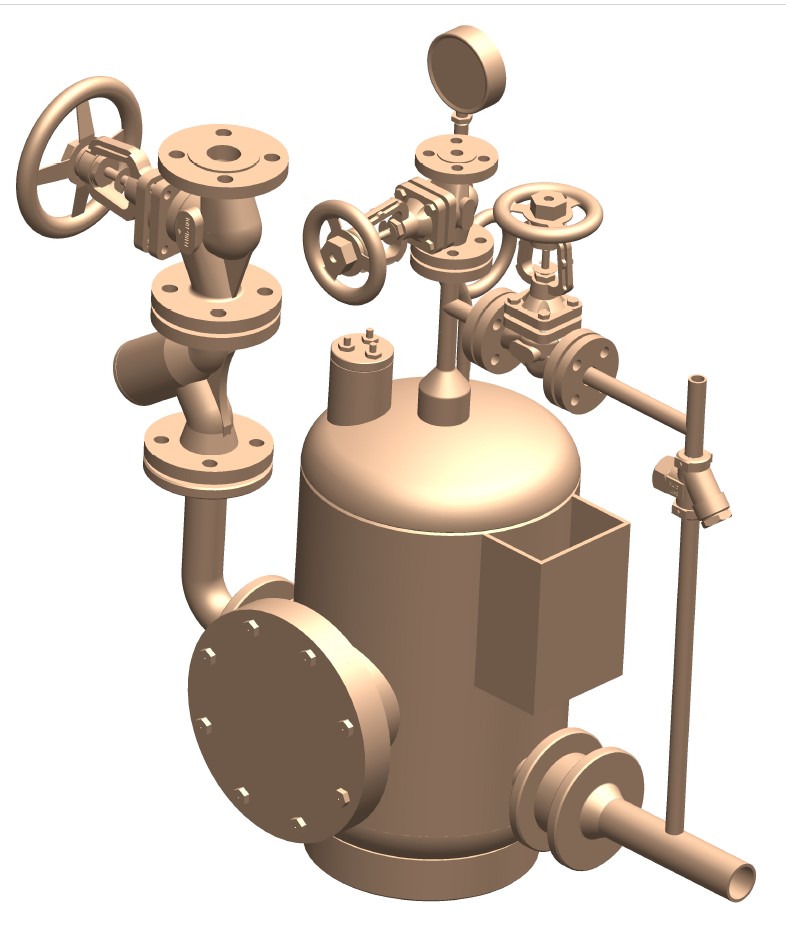

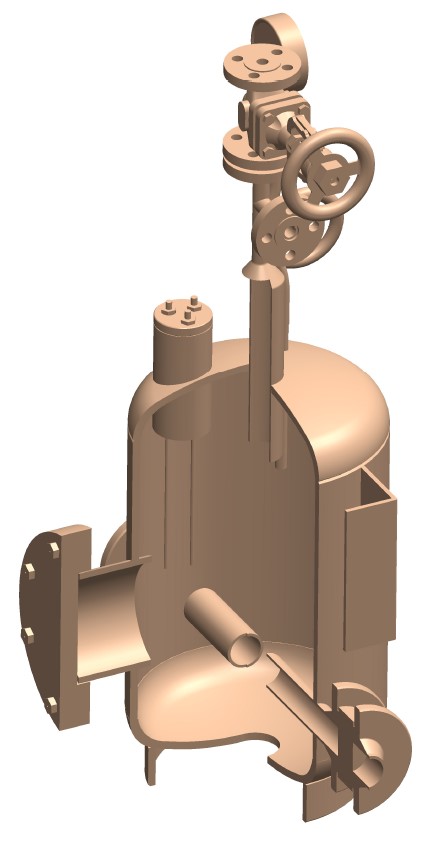

Deaerator Plant System

To avoid corrosion damage in steam boilers, the levels of corrosive gases such as oxygen and carbon dioxide in the feedwater must be minimized. The Deaerator Plant System is designed to remove these gases effectively, ensuring high-quality feedwater for boilers. The Thai Technical Regulatory Association provides guidelines for boiler feedwater quality, which boiler manufacturers adhere to in order to guarantee the performance and longevity of their boilers. Thermal deaeration, in addition to chemical treatment, is crucial for maintaining the required feedwater quality.By implementing a Deaerator Plant System, you can ensure the delivery of high-quality feedwater, protecting your boiler system from corrosion and improving its efficiency. If you need further details or assistance in selecting the right deaerator system for your application, feel free to contact us!

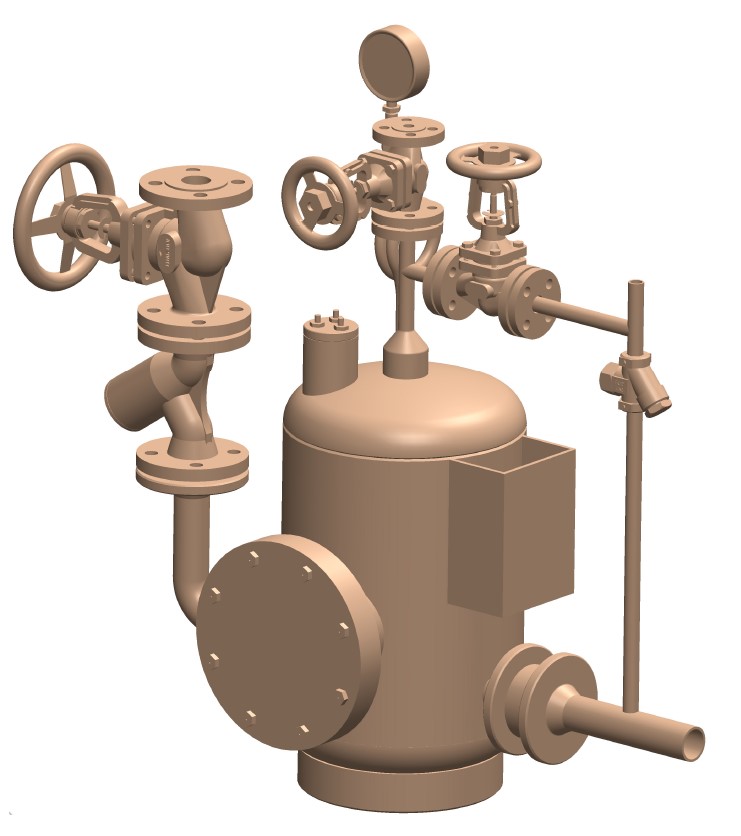

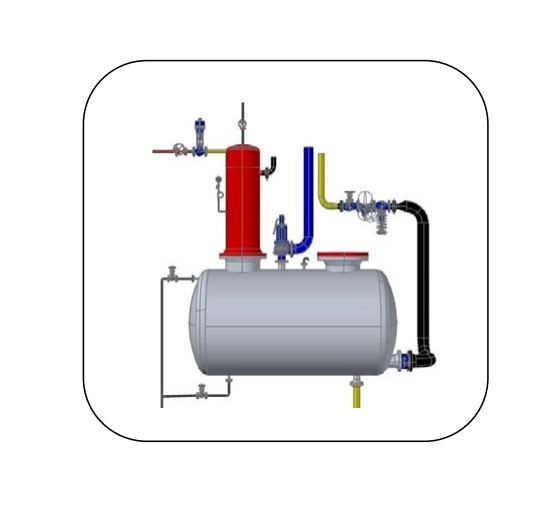

Condensate Recovery System

Returning condensate to the boiler is essential for the efficiency of a high-performance steam generation system. For applications requiring pressure-assisted condensate return, we offer the Condensate Recovery System with pumps specifically designed to meet your system’s needs.By implementing a Condensate Recovery System, you can maximize the efficiency of your steam system, reduce operational costs, and promote sustainability. If you need further details or assistance in selecting the right system for your application, feel free to contact us!

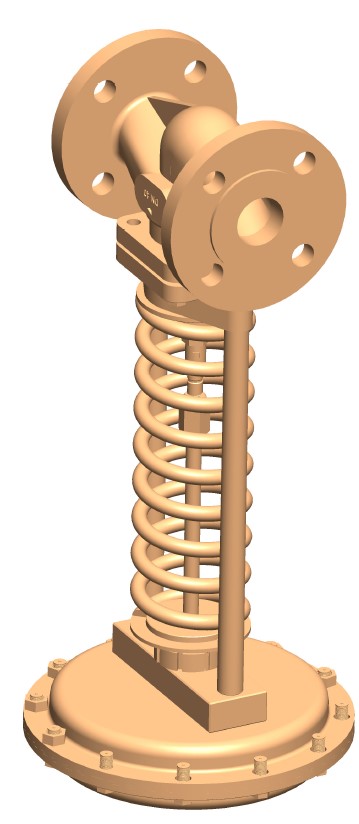

Damping Pot

The Damping Pot is a device used to collect condensate and reduce water hammer, minimizing the impact of pressure surges in steam systems. It allows condensate to be discharged quietly and efficiently, ensuring smooth and safe operation.By incorporating a Damping Pot into your steam system, you can ensure smooth and safe operation, protecting your equipment and improving system efficiency. If you need further details or assistance in selecting the right damping pot for your application, feel free to contact us!

Flash Recovery System

The Flash Recovery System utilizes a Flash Vessel to recover energy from high-pressure condensate that is released into a low-pressure system. When high-pressure condensate is discharged into the flash vessel, it generates flash steam due to the energy balance within the system. The flash steam is separated from the water and fed into the low-pressure steam system, while the remaining condensate is drained to a condensate tank.By implementing a Flash Recovery System, you can maximize energy recovery, reduce operating costs, and improve the sustainability of your steam system. If you need further details or assistance in selecting the right system for your application, feel free to contact us!

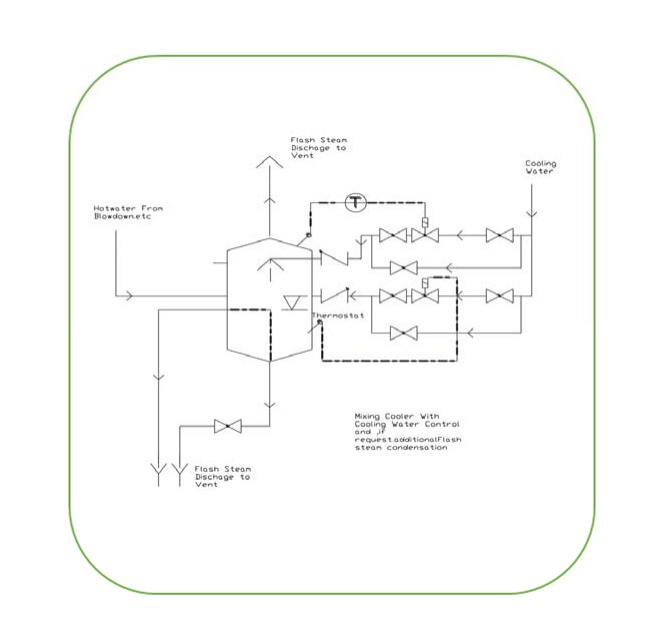

Mixing Cooler

Mixing Coolers are tanks designed to receive blowdown water from boilers and mix it with cold water to reduce its temperature. This process cools the hot wastewater, making it safe to discharge into a drain or sewer system.By using a Mixing Cooler, you can safely and efficiently manage the discharge of hot blowdown water, ensuring compliance with environmental regulations and protecting your drainage systems. If you need further details or assistance in selecting the right mixing cooler for your application, feel free to contact us!