Looking for FLUID LINE products and services?

Pipe Ancillary

Dry, clean steam is crucial for the longevity of steam equipment and the reliability of operations in your plant. Investing in high-quality pipe ancillary systems is cost-effective compared to the expenses of plant maintenance, ensuring continuous operation without the need for frequent shutdowns for repairs.

Pipe Ancillary: Importance and Benefits

- Dry, Clean Steam:

- Steam free from moisture and contaminants extends the lifespan of steam equipment such as valves, pipes, boilers, and heat exchangers.

- Reduces issues like corrosion and scale buildup in the system.

- Uninterrupted Production:

- Investing in quality pipe ancillary systems minimizes the risk of operational downtime, allowing your plant to run continuously.

- Lower Maintenance Costs:

- Preventing problems caused by wet or contaminated steam reduces repair and maintenance expenses.

- Improved System Efficiency:

- Dry, clean steam enhances heat transfer efficiency and reduces energy losses.

Key Components of Pipe Ancillary:

- Steam Traps:

- Remove condensate (water formed from condensed steam) from the system without allowing steam to escape.

- Strainers:

- Filter out dirt and particles from steam before it enters equipment.

- Separators:

- Remove moisture and liquids from steam to ensure dry steam.

- Control Valves:

- Regulate steam flow and pressure within the system.

- Pressure Reducing Valves (PRV):

- Reduce steam pressure to the required level for specific applications.

- Thermostatic Air Vents:

- Vent air from the system to prevent airlocks.

Benefits of Using Pipe Ancillary:

- Extended Equipment Lifespan:

- Prevents corrosion and wear on steam equipment.

- Reduced Plant Downtime:

- Ensures continuous operation without frequent maintenance shutdowns.

- Energy Savings:

- Dry, clean steam improves system efficiency and reduces energy waste.

- Safety and Reliability:

- Minimizes the risk of accidents or damage caused by wet or contaminated steam.

Applications:

- Steam systems in industrial plants

- Heating systems

- Power plants

- Food and beverage production facilities

- Chemical and pharmaceutical plants

Investing in high-quality Pipe Ancillary systems not only extends the lifespan of your steam equipment but also ensures continuous and efficient plant operations. If you need further information or advice on pipe ancillary systems, feel free to contact us anytime!

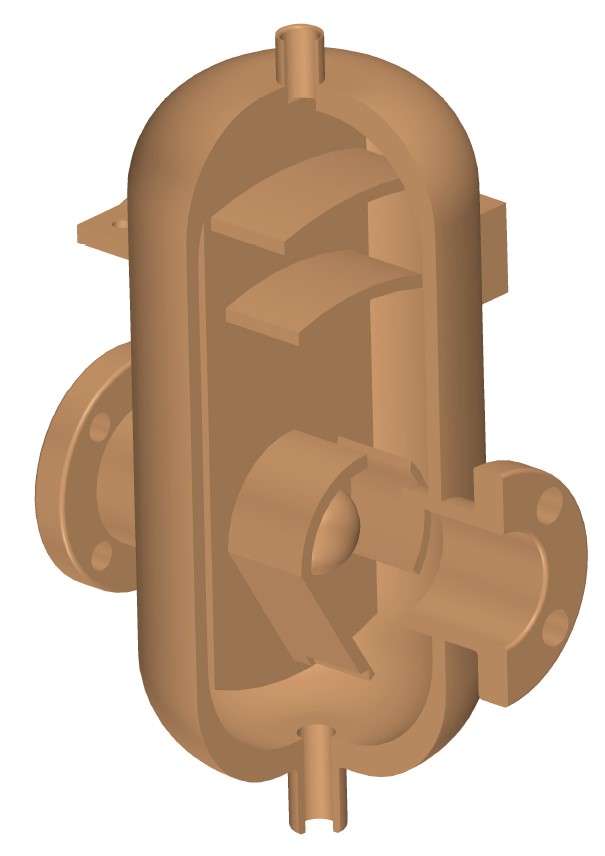

Steam Separator

A Steam Separator is designed to collect and remove fine water droplets (moisture) and contaminants from steam, ensuring that the steam is dry and clean, ready for use. This device plays a critical role in improving the quality of steam, which is essential for the efficient and reliable operation of steam systems.

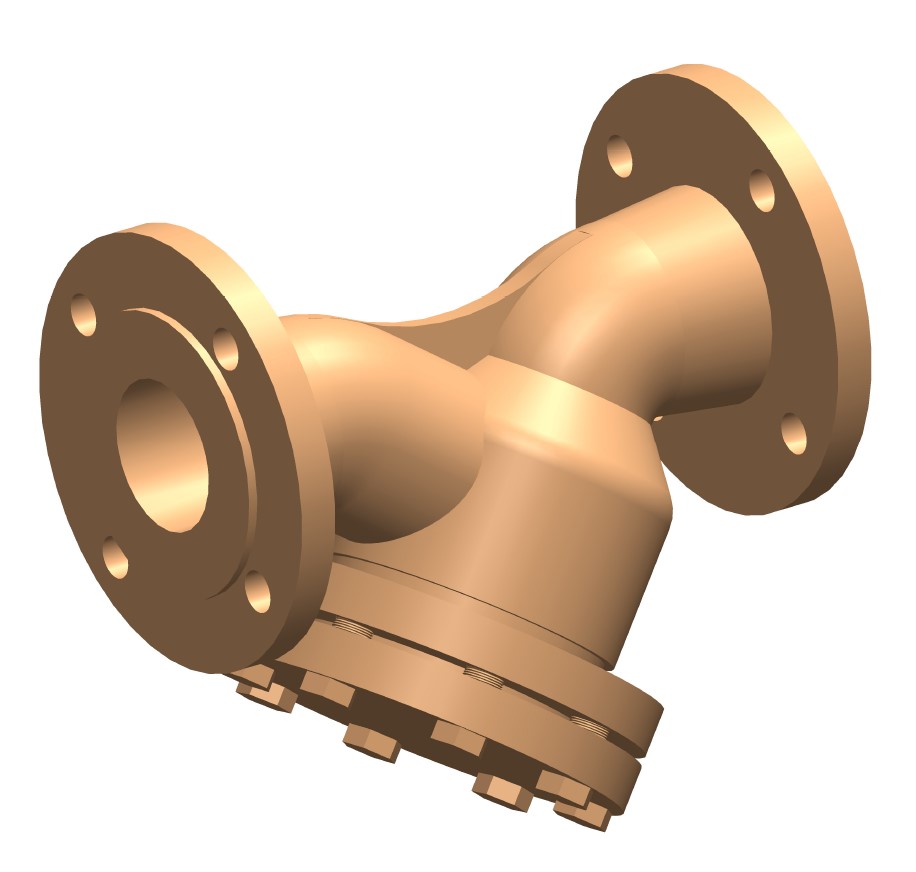

Strainer

A Strainer is a high-efficiency filtration device designed to remove impurities and foreign particles from steam, ensuring improved steam quality. It is an essential component in steam systems to protect downstream equipment, enhance system efficiency, and maintain the reliability of operations.

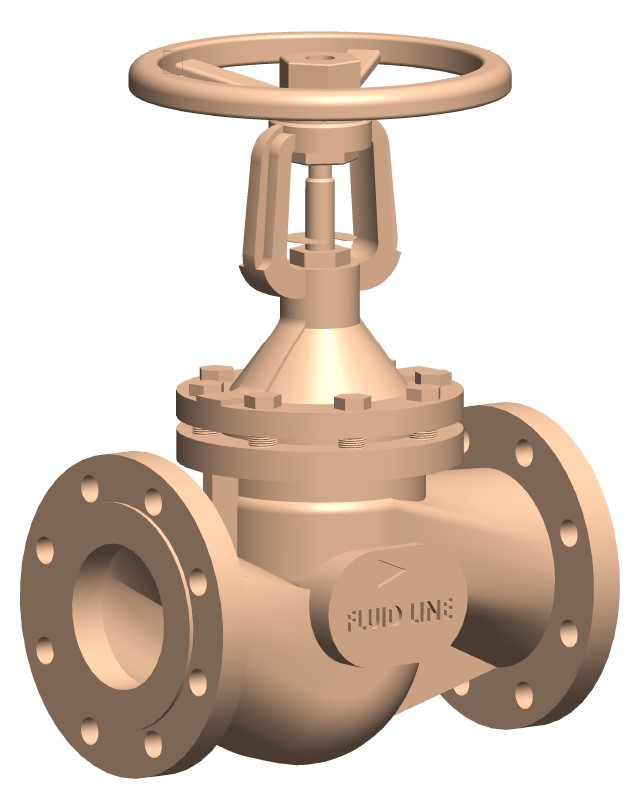

Bellow Seal Globe Valve

The Bellow Seal Globe Valve from Fluid Line is an engineered valve designed to ensure safety and reliability in industrial plants. It is specifically designed to provide a leak-proof sealing solution, making it ideal for applications involving hazardous, toxic, or high-purity fluids such as steam, gases, and chemicals. The bellows seal prevents leakage along the valve stem, ensuring safe and efficient operation in critical environments.านและประหยัดพลังงานโดยกำจัดการรั่วไหล คอวาล์ว โดยสิ้นเชิง

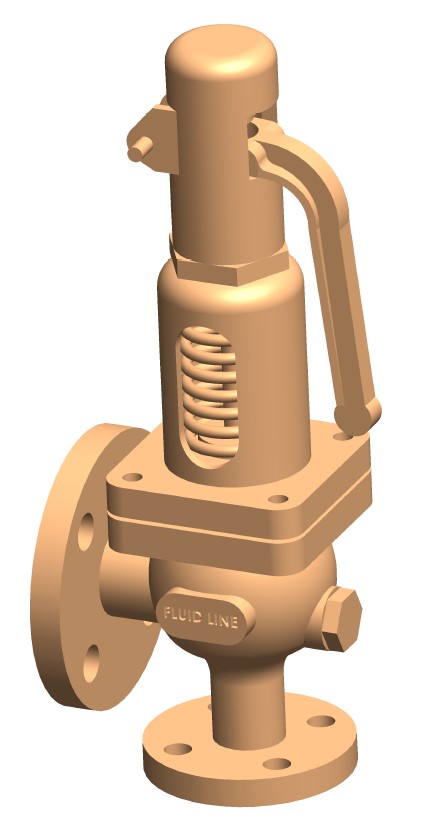

Safety Valve

A Safety Valve is a critical device in any system where overpressure conditions may occur, which can cause damage to machinery and facilities. The safety valve automatically releases excess pressure from the system to prevent potential damage to equipment and ensure the safety of personnel.