Looking for FLUID LINE products and services?

Mixing Cooler (Blowdown Vessel)

Maintaining water quality in boilers is crucial to ensure that your boiler operates at full efficiency and safely during the steam generation process. Periodic and continuous blowdown of boiler water is discharged into a collection tank and cooled before being released into the drainage system. The Mixing Cooler from FLUID LINE is designed to handle high temperatures, high pressure, and the corrosive effects of sludge and settled solids effectively, ensuring the safe discharge of wastewater in compliance with legal regulations.

Key Functions of the Mixing Cooler (Blowdown Vessel):

- Temperature Reduction:

- The blowdown water from the boiler is extremely hot. The Mixing Cooler reduces its temperature to a safe level before discharge.

- Protection of Piping and Equipment:

- Direct discharge of high-temperature water can damage drainage pipes and equipment. The Mixing Cooler prevents this by cooling the blowdown water.

- Compliance with Environmental Regulations:

- Discharging hot or contaminated water into public drainage systems may violate environmental laws. The Mixing Cooler ensures compliance with environmental standards.

- Handling Sludge and Solids:

- The Mixing Cooler from FLUID LINE is designed to withstand corrosion and effectively manage sludge and settled solids in the blowdown water.

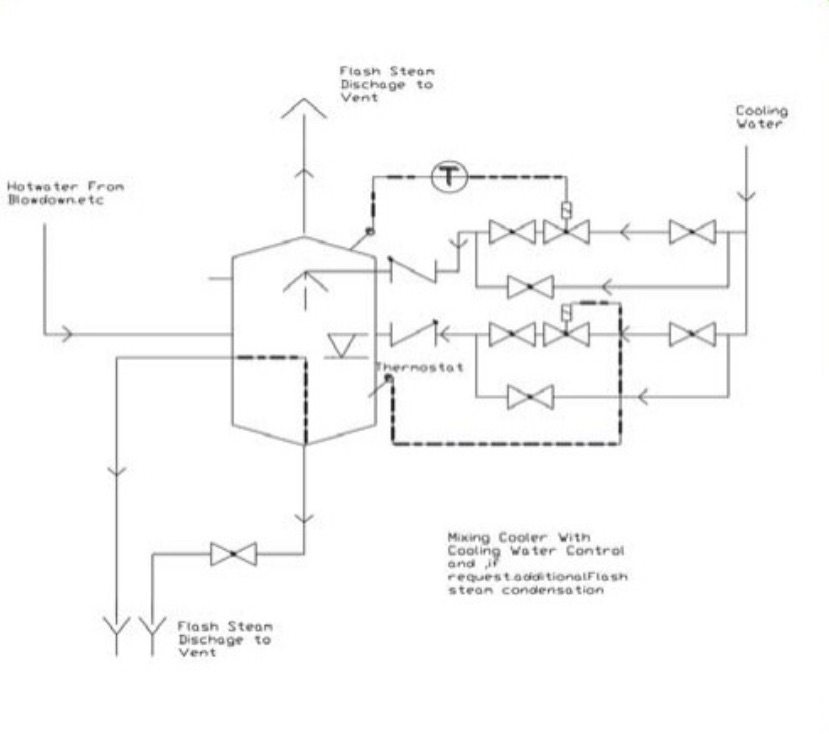

Main Components of the Mixing Cooler:

- Mixing Vessel:

- Mixes hot blowdown water with cool or cooling water to reduce its temperature.

- Temperature Control System:

- Regulates the flow of blowdown water and cooling water to achieve the desired temperature before discharge.

- Valves and Pipes:

- Control valves and pipes for directing blowdown water and cooling water into the system.

- Safety Relief System:

- Prevents overpressure in the system and enhances operational safety.

Benefits of the Mixing Cooler (Blowdown Vessel):

- Improved Boiler Efficiency:

- Helps maintain water quality in the boiler and prevents issues such as scale buildup and corrosion.

- Energy and Water Savings:

- Reduces energy and water losses by efficiently managing blowdown water.

- Safety and Environmental Friendliness:

- Safely discharges treated and cooled wastewater in compliance with legal requirements.

- Durability and Reliability:

- Designed to withstand harsh operating conditions, including high temperatures, high pressure, and corrosion.

Applications:

- Industrial boiler systems

- Power plants

- Heating systems

- Food and beverage production facilities

- Chemical and pharmaceutical plants

If you need further information about the Mixing Cooler (Blowdown Vessel) from FLUID LINE or assistance in selecting the right equipment for your system, feel free to contact us anytime!

Benefits of Mixing cooler

| Easy to install. | Wear to resistance | Long life use |

| Document | Reference Number | Download |

| (Mixing Cooler) VDM | TI-01-0011 |