Looking for FLUID LINE products and services?

Heat Recovery System by Fluid Line: Comprehensive Solutions for Steam and Condensate Systems

Fluid Line specializes in designing, manufacturing, and delivering turnkey heat recovery systems tailored to meet the specific needs of steam and condensate systems. Our solutions are designed to maximize energy efficiency, reduce operational costs, and ensure optimal performance for your boiler plant. From flash steam recovery to condensate return systems and de-aerating plants, Fluid Line provides fully integrated, ready-to-use equipment that can be customized to fit your unique processes and applications.

Key Features of Fluid Line’s Heat Recovery Systems:

- Turnkey Solutions:

Fluid Line offers end-to-end services, including design, manufacturing, installation, and commissioning, ensuring a seamless experience for customers. - Customizable Designs:

Our systems are tailored to match your specific operational requirements, ensuring maximum efficiency and performance. - Energy Efficiency:

By recovering waste heat and reusing it in your processes, our systems help reduce energy consumption and lower operational costs. - Pre-Engineered Equipment:

Our ready-to-use systems are designed for quick installation and reliable performance, minimizing downtime. - Comprehensive Support:

From initial consultation to after-sales service, Fluid Line provides complete support to ensure your system operates at peak efficiency.

Core Components of Fluid Line’s Heat Recovery Systems:

- Flash Steam Recovery System:

Captures and reuses flash steam generated from high-pressure condensate, converting waste energy into usable heat for low-pressure applications. - Condensate Return System:

Collects and returns condensate to the boiler, reducing water and energy consumption while improving system efficiency. - De-aerating Plant:

Removes dissolved oxygen and other gases from boiler feed water, preventing corrosion and extending the lifespan of your equipment. - Heat Exchangers:

Transfers heat from waste streams to other processes, maximizing energy recovery and reducing fuel costs. - Customized Control Systems:

Ensures precise operation and monitoring of the heat recovery system for optimal performance.

Benefits of Fluid Line’s Heat Recovery Systems:

- Energy Savings:

Recovers waste heat and reuses it, reducing the need for additional energy input. - Cost Reduction:

Lowers fuel and water consumption, reducing operational expenses. - Improved Efficiency:

Enhances the overall performance of your boiler plant and steam systems. - Environmental Sustainability:

Reduces carbon emissions and promotes sustainable energy practices. - Reliable Operation:

High-quality equipment and expert installation ensure long-term reliability and minimal maintenance.

Applications:

- Power Plants:

Recovers waste heat from turbines and condensate systems for reuse in low-pressure processes. - Industrial Facilities:

Maximizes energy efficiency in manufacturing, chemical processing, and food production. - Heating Systems:

Utilizes recovered heat for space heating or preheating applications. - Boiler Plants:

Improves boiler efficiency by recovering heat from condensate and flash steam.

Why Choose Fluid Line?

- Expertise in Steam Systems:

Decades of experience in designing and manufacturing heat recovery solutions for steam and condensate systems. - Customized Solutions:

Tailored designs to meet the unique needs of your processes and applications. - High-Quality Standards:

Our equipment is built to last, ensuring reliable performance in demanding environments. - Comprehensive Service:

From design to installation and support, Fluid Line provides a complete solution for your heat recovery needs.

Conclusion

Fluid Line’s Heat Recovery Systems offer a comprehensive, energy-efficient solution for optimizing steam and condensate systems in industrial and commercial applications. By recovering waste heat, reusing condensate, and ensuring high-quality feed water, our systems help you achieve significant energy savings, reduce operational costs, and improve the sustainability of your operations. Trust Fluid Line to deliver customized, turnkey solutions that maximize the efficiency and performance of your boiler plant.

Condensate Return System: Efficient Collection and Return of Condensate

The Condensate Return System is a critical component in steam systems, designed to efficiently collect and return condensate (the liquid formed when steam condenses) back to the boiler or other points of use. This system plays a vital role in improving energy efficiency, reducing water and fuel consumption, and lowering operational costs in industrial and commercial steam systems.ปยังถังป้อนน้ำเข้า boiler

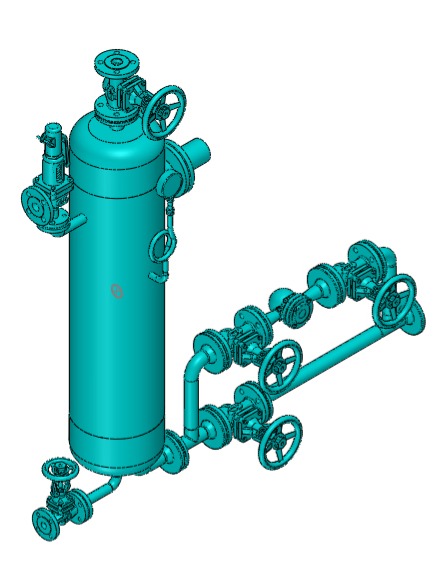

Feed Water De-aerating System: Removing Oxygen and Non-Condensable Gases

The Feed Water De-aerating System, or Deaerator, is a crucial component in steam systems designed to remove oxygen and other non-condensable gases from boiler feed water. These gases, particularly oxygen (O₂) and carbon dioxide (CO₂), are major contributors to corrosion and inefficiency in steam systems. By eliminating these gases, the deaerator ensures the longevity, safety, and optimal performance of boilers and associated equipment.ากน้ำที่ป้อนเข้าboiler

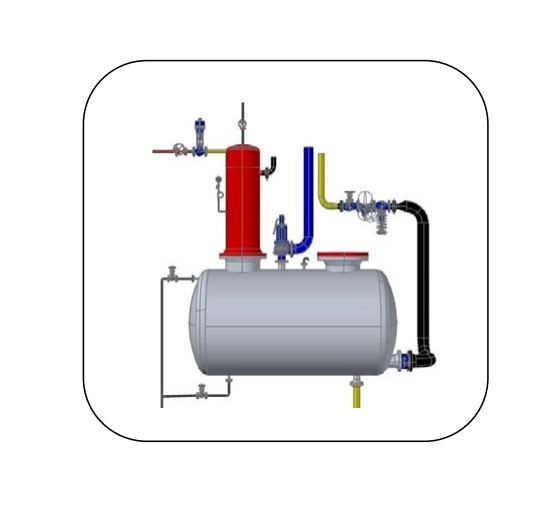

Flash Steam Recovery System: Reducing Operational Costs and Saving Energy

The Flash Steam Recovery System is designed to capture and reuse flash steam generated when high-pressure condensate or hot water is depressurized. This system plays a critical role in reducing operational costs and improving energy efficiency in industrial processes by recovering valuable thermal energy that would otherwise be wasted.ม่

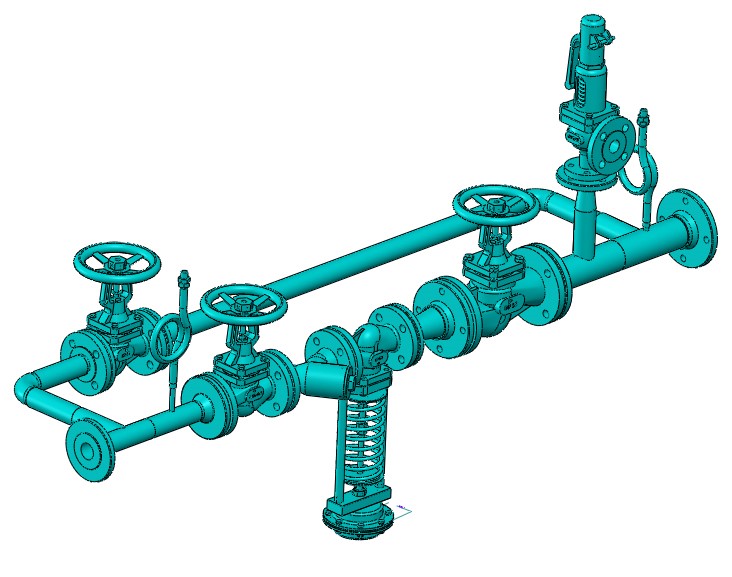

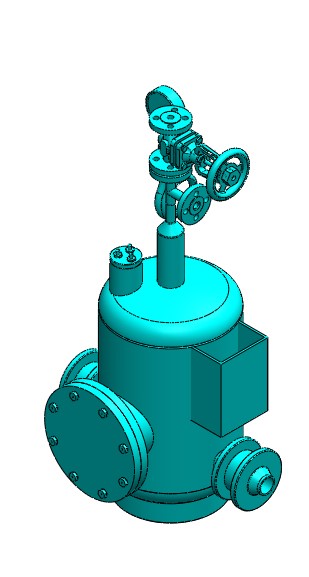

Pressure Reducing Valve Station

A pre-assembled unit designed to reduce the pressure of steam from a higher inlet pressure to a lower, controlled outlet pressure, ensuring safe and efficient operation in steam systems. It typically includes components such as a pressure reducing valve (PRV), safety valve, strainer, steam trap, pressure gauges, and isolation valves, all integrated into a compact and ready-to-install system. This station is commonly used in industrial, commercial, and heating applications where precise steam pressure control is required.

Condensate Damping Pot

A Condensate Damping Pot (or Condensate Pot) is a device used in steam systems to minimize water hammer and protect steam piping and equipment. Water hammer occurs when condensate (water formed from condensed steam) accumulates in the steam lines and is struck by high-velocity steam, causing sudden pressure surges that can damage pipes, valves, and other components. The damping pot helps mitigate this issue by collecting and managing condensate effectively.กค้าจากความเสียหายเมื่อคอนเดนเสทถูกส่งกลับและยกระดับขึ้นสู่ท่อเมนหลักเพื่อนำคอนเดนเสทกลับสู่ถังป้อนน้ำเข้า boiler

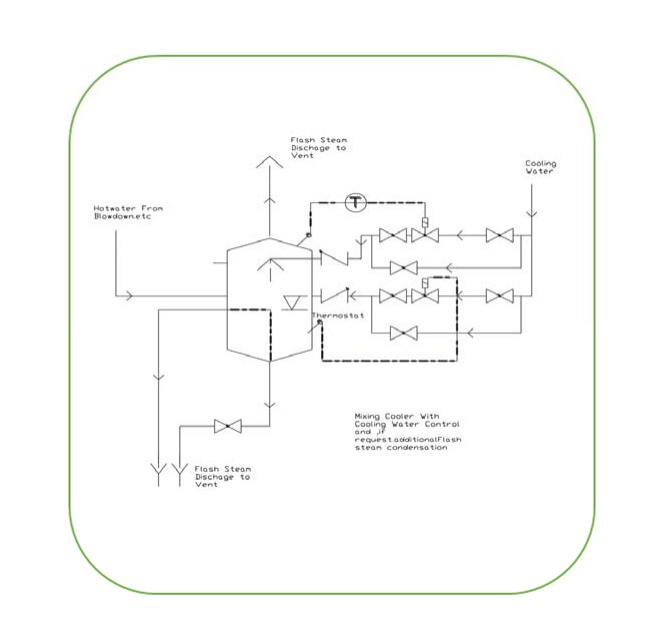

Mixing Cooler System

A Mixing Cooler System is a device used in boiler systems to manage and cool hot blowdown water (wastewater) from the boiler. It is often integrated with a Flash Tank to efficiently reduce the temperature of the hot water before disposal or further treatment. This system helps protect downstream equipment and ensures safe handling of high-temperature wastewater.ก่อนปล่อยลงทิ้งสู่ท่อระบายน้ำ

Booster Pump BT

The Booster Pump BT is specifically designed to maximize the return of condensate in steam systems, with a capacity of up to 10 tons per hour (10 t/h). This pump plays a critical role in improving the efficiency of steam systems by recovering and reusing condensate, which is the hot water formed when steam loses its heat energy and condenses. By returning condensate to the boiler, the system reduces energy consumption, water usage, and operating costs.ะ แรงดันใช้งานสูงสุด10 bar.