Looking for FLUID LINE products and services?

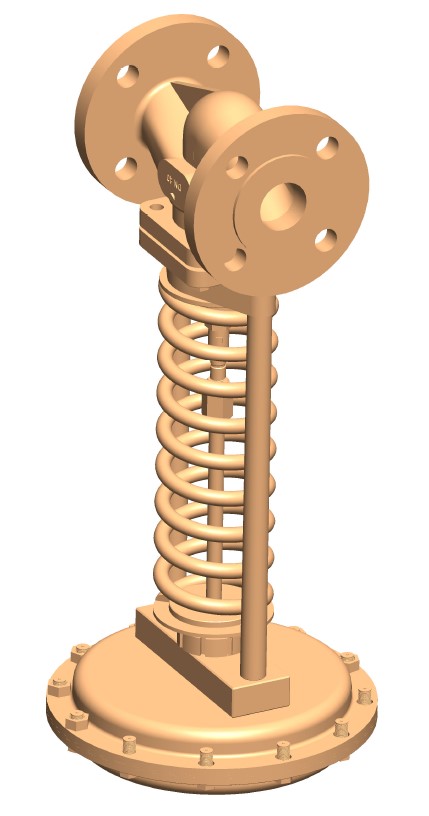

Steam Direct-Acting Pressure Reducing Valve

The Steam Direct-Acting Pressure Reducing Valve is a valve designed to control and reduce steam pressure in steam systems to a desired level. This type of valve operates directly, meaning it uses the force of the steam flowing through the valve to control its opening and closing, without requiring external power sources such as electricity or compressed air.

Key Features:

- Self-Operating Design:

The valve operates using the energy from the steam itself, eliminating the need for external power sources. - Precise Pressure Control:

Maintains consistent downstream pressure, even with fluctuations in upstream pressure or flow rates. - Compact and Simple Construction:

Easy to install and maintain, with fewer components compared to externally powered valves. - Durable and Reliable:

Built to withstand high temperatures and pressures, ensuring long-lasting performance in steam systems. - Cost-Effective:

No external power requirements reduce operational costs and complexity.

How It Works:

- Steam Flow:

Steam enters the valve at a high pressure. - Pressure Reduction:

The valve’s internal mechanism (such as a diaphragm or piston) adjusts based on the downstream pressure, reducing the steam pressure to the desired level. - Automatic Adjustment:

The valve continuously monitors and adjusts the opening to maintain a stable downstream pressure, even if the upstream pressure or flow rate changes.

Applications:

- Steam Systems in Industrial Plants:

Used to control steam pressure for processes, heating, and equipment. - HVAC Systems:

Regulates steam pressure in heating systems for buildings. - Power Plants:

Ensures safe and efficient steam pressure for turbines and other equipment. - Food and Beverage Industry:

Maintains precise steam pressure for sterilization and cooking processes.

Benefits:

- Energy Efficiency:

Maintains optimal steam pressure, reducing energy consumption and improving system efficiency. - Low Maintenance:

Simple design with fewer moving parts minimizes maintenance requirements. - Reliable Performance:

Provides consistent pressure control, ensuring safe and efficient operation of steam systems. - Cost Savings:

No need for external power sources reduces installation and operational costs.

Why Choose a Steam Direct-Acting Pressure Reducing Valve?

- Proven Technology:

Reliable and widely used in various industries for steam pressure control. - High-Quality Materials:

Constructed from durable materials to withstand harsh steam conditions. - Ease of Installation:

Compact design allows for easy integration into existing systems.

Conclusion

The Steam Direct-Acting Pressure Reducing Valve is an essential component for controlling and reducing steam pressure in industrial and commercial steam systems. Its self-operating design, precise control, and durability make it a cost-effective and reliable solution for maintaining optimal steam pressure. Whether for industrial processes, HVAC systems, or power plants, this valve ensures efficient and safe operation, helping you save energy and reduce operational costs. Trust Fluid Line to provide high-quality pressure reducing valves that meet your steam system needs.

Benefits of Direct acting pressure reducing valve.

| Self-acting without auxiliary energy. | For use in hazardous area | Good for flow dynamics | Long Service life and operation reliability |

| Document | Reference Number | Download |

| Direct acting pressure reducing valve. DRV3 | TI-01-007 |