Looking for FLUID LINE products and services?

Control System

Fluid Line’s Diverse Range of Control Valves: Precision and Reliability for Steam, Water, and Hot Oil Applications

Fluid Line offers a wide variety of control valves designed for applications and processes involving steam, water, and hot oil, where precise control of temperature or pressure is required. Our control valves are engineered to be accurate, reliable, and durable, making them the ideal solution for effectively managing steam, water, and other fluids. With deep expertise in steam, condensate, and fluid systems, combined with high-quality design and manufacturing standards, customers can trust Fluid Line’s control valves to enhance production efficiency and minimize downtime, ensuring optimal performance in their facilities.

Key Features of Fluid Line Control Valves:

- Precision Control:

Designed to provide accurate control of temperature and pressure in various industrial processes. - Reliability and Durability:

Built to withstand demanding conditions, ensuring long-lasting performance with minimal maintenance. - Versatility:

Suitable for a wide range of applications, including steam, water, and hot oil systems. - Expertise in Steam and Condensate Systems:

Leveraging extensive knowledge in steam, condensate, and fluid dynamics to deliver optimal solutions. - High-Quality Standards:

Manufactured to meet stringent quality standards, ensuring consistent performance and reliability.

Applications:

- Hot Water Systems:

Ideal for controlling temperature and pressure in hot water applications, ensuring efficient and reliable operation. - Hot Oil Systems:

Perfect for managing hot oil processes, providing precise control to maintain optimal operating conditions. - Steam Systems:

Designed to handle steam applications, ensuring accurate control and energy efficiency. - Condensate Management:

Effective in managing condensate return systems, improving overall system efficiency.

Benefits:

- Improved Production Efficiency:

Enhances process control, leading to higher productivity and reduced operational costs. - Reduced Downtime:

Durable and reliable design minimizes maintenance requirements and unplanned downtime. - Energy Savings:

Precise control of temperature and pressure helps optimize energy usage. - Customizable Solutions:

Tailored to meet specific customer needs, ensuring the best fit for each application.

Why Choose Fluid Line Control Valves?

- Proven Expertise:

Decades of experience in designing and manufacturing control valves for steam, water, and hot oil systems. - Quality Assurance:

High-quality materials and manufacturing processes ensure long-term reliability. - Customer-Centric Approach:

Dedicated to providing solutions that maximize efficiency and performance for our customers.

Conclusion

Fluid Line’s control valves are the perfect choice for industries requiring precise and reliable control of steam, water, and hot oil systems. With a focus on quality, durability, and performance, our valves help customers achieve maximum efficiency, reduce downtime, and optimize their production processes. Whether for hot water, hot oil, or steam applications, Fluid Line’s control valves deliver the precision and reliability needed to meet the demands of modern industrial operations.

Two Port Control Valve

Fluid Line’s Precision Control Valves: Compact, Versatile, and Durable

Fluid Line’s precision control valves are designed to meet the demands of modern industrial applications. These valves are compact, versatile, and highly durable, making them ideal for a wide range of uses in steam, water, and hot oil systems. Whether you need precise temperature or pressure control, Fluid Line’s control valves deliver reliable performance in a compact and efficient design.

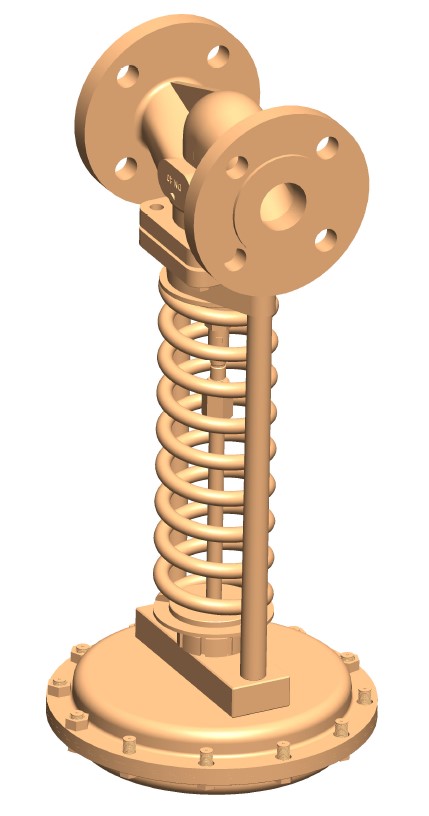

Direct-Acting Pressure Reducing Valve by Fluid Line

Controlling pressure has never been easier with Fluid Line’s Direct-Acting Pressure Reducing Valve. This self-operating valve is designed to provide precise and reliable pressure control in various industrial applications, ensuring optimal performance and efficiency

Bottom Blowdown Valve: Ensuring Boiler Water Quality and Efficiency

The Bottom Blowdown Valve is a critical component in maintaining the quality of water inside a boiler. It ensures that the boiler operates efficiently and meets the standards set by boiler manufacturers by effectively removing sediment and impurities that accumulate at the bottom of the boiler.